Wet Milling | 11 Variables to Consider Before Buying a Media Mill

Overview

When it comes to industrial wet milling and dispersion processes, choosing the right equipment and parameters can be a daunting task. The optimal milling solution depends on a multitude of variables, each of which can significantly impact the efficiency and quality of your process.

In this post, we’ll dive into the complex world of industrial milling and highlight 11 key variables to consider when selecting the right equipment for your specific application.

Before diving in, if you already feel overwhelmed, the Schold team is here to assist. Discuss your process with us and we will guide you to the optimal solution. And to go a step further, we can schedule an on-site consultation to give recommendations on your current process.

Overview

When it comes to industrial wet milling and dispersion processes, choosing the right equipment and parameters can be a daunting task. The optimal milling solution depends on a multitude of variables, each of which can significantly impact the efficiency and quality of your process.

In this post, we’ll dive into the complex world of industrial milling and highlight 11 key variables to consider when selecting the right equipment for your specific application.

Before diving in, if you already feel overwhelmed, the Schold team is here to assist. Discuss your process with us and we will guide you to the optimal solution. And to go a step further, we can schedule an on-site consultation to give recommendations on your current process.

Overview

When it comes to industrial wet milling and dispersion processes, choosing the right equipment and parameters can be a daunting task. The optimal milling solution depends on a multitude of variables, each of which can significantly impact the efficiency and quality of your process.

In this post, we’ll dive into the complex world of industrial milling and highlight 11 key variables to consider when selecting the right equipment for your specific application.

Before diving in, if you already feel overwhelmed, the Schold team is here to assist. Discuss your process with us and we will guide you to the optimal solution. And to go a step further, we can schedule an on-site consultation to give recommendations on your current process.

1. Material Properties

- Material Hardness: The hardness of your material affects the choice of milling equipment and milling media.

- Material Viscosity: Viscous materials might necessitate specialized equipment to handle the increased resistance.

- Material Particle Size Distribution: The initial particle size distribution of your material will impact the milling process and final product quality.

- Material Chemistry and Reactivity: Material chemistry can influence the choice of additives and chemicals used for dispersion and equipment materials of construction.

- Material Density, Solubility, and Compressibility: These properties impact the material’s behavior during milling and the resulting product quality.

- Water-Based or Solvent-Based: The choice of solvent or dispersion medium is essential for compatibility with your material.

- % Solids and pH: These variables can influence the stability and quality of the dispersion or milling process.

2. Equipment Factors

- Type of Milling Equipment: Selecting the right equipment, whether it’s a horizontal media mill, vertical media mill, or immersion mill, is a crucial step. Additionally, the best pre-mix equipment is equally important (high-speed disperser, inline disperser, low-speed mixer/blender, or a combination).

- Equipment Capacity and Throughput: Match the equipment capacity to your production and facility requirements.

- Milling Chamber Design: The design of the milling chamber affects material flow and milling efficiency.

- Agitator Speed and Design: The agitator’s speed and design influence the movement and dispersion of the material.

- Milling Media Type and Size: The choice of media has a significant impact on particle size reduction and quality.

- Cooling or Heating Mechanisms: Temperature control is essential for maintaining product integrity.

- Equipment Wear Resistance: Consider wear-resistant components for abrasive materials.

- Equipment Maintenance Requirements: Maintenance impacts downtime and operational costs.

- Equipment Footprint and Space Constraints: Consider space limitations when choosing equipment.

- Mill Type, Discs, Number of Mill Discs: Specifics about the type of mill and milling discs can be critical.

- Media Separation System and Gap: The separation system affects mill performance.

- Milling Shaft RPM and Disc Tip Speed: These parameters are crucial for the milling process.

- Feed System: The type of feed system affects the material’s entry into the milling chamber and output rates.

- Pump Type and Flow Rate: The pump system is important for maintaining a consistent flow of material.

- Inlet and Outlet Pipe Dimensions: Proper sizing of inlet and outlet pipes is essential for efficient milling.

3. Process Parameters

- Residence Time and Flow Rate: Controlling residence time and flow rate impacts product quality.

- Agitator or Rotor Speed and Energy Input: The speed and energy input influence particle size reduction.

- Milling Time: Longer milling times may be necessary for specific materials.

- Recirculation Rate and Batch vs. Continuous Operation: Choose the appropriate recirculation rate and operation mode for your process.

- Inlet and Outlet Conditions: Proper control of inlet and outlet conditions is vital.

- Control of Process Variables: Maintaining control over critical variables like pressure, temperature, and pH is essential.

- Separation and Classification Mechanisms: The method used to separate milled particles affects product quality.

4. Particle Size and Distribution

- Desired Particle Size: Your target particle size is a fundamental consideration.

- Particle Size Distribution Requirements: Meeting distribution requirements is crucial for product quality.

- Particle Size Analysis Techniques: Proper analysis tools are necessary for quality control.

- Monitoring and Control Methods: Implement real-time monitoring for process optimization.

- Particle Size Reduction Mechanism: Understand the mechanism by which particle size is reduced (e.g., crushing, impact, attrition).

5. Additives and Chemicals

- Use of Dispersants, Surfactants, or Stabilizers: Proper use of additives can enhance dispersion.

- Chemical Reactions During Milling: Be aware of any chemical reactions taking place during milling.

- Compatibility with Materials: Ensure compatibility between materials and additives.

- Concentration and Dosing of Additives: The right dosage is crucial for the desired effect.

6. Product Quality and Characteristics

- Desired Product Properties: Understand what qualities your product should possess (e.g., color, texture, taste).

- Product Yield and Stability: Consider the yield and stability of the final product.

- Risk of Contamination: Minimize the risk of contamination during the process.

- Homogeneity of the Final Product: Ensure product uniformity.

- Surface Area and Specific Surface Properties: Specific surface area can impact product characteristics.

- Product Particle Size Distribution: The product’s particle size distribution directly affects its quality and performance.

7. Cost and Efficiency

- Equipment Cost: Weigh the initial investment in equipment against long-term savings.

- Operating Cost: Consider ongoing operating expenses, including energy costs.

- Energy Efficiency: Efficient processes can save on energy costs.

- Maintenance Requirements: Low-maintenance equipment reduces downtime and costs.

- Total Cost of Ownership: Evaluate the total cost of owning and operating your milling equipment.

- Cost of Milling Media: Media costs can add up over time.

- Cost of Waste Disposal: Proper waste management is essential for cost control.

8. Scale of Operation

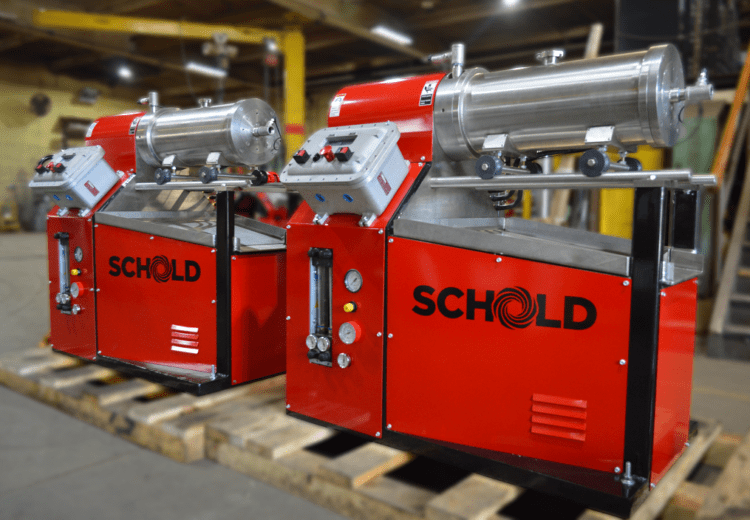

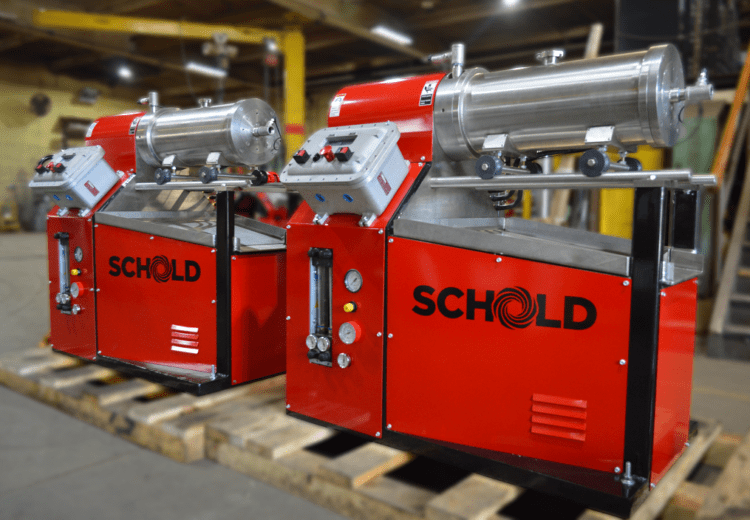

- Laboratory/Pilot-Scale vs. Large-Scale: Choose equipment that matches your production scale. Schold has various options for this – the EMI Lab Media Mill is a great option for lab/pilot batches and the Horizontal (or Vertical) Media Mill is ideal for larger-scale production.

- Scalability of the Milling Process: Ensure that your chosen process can scale up as needed.

- Pilot-Scale Testing and Validation: Pilot-scale testing can help optimize your process before full-scale production.

9. Material Handling and Feeding

- Material Feed Mechanism and Feed Rate Control: Proper material feeding is vital for consistent processing.

- Material Addition into Premix: Ensure accurate addition of materials into the premix.

- Cut Bags, Super Sacs, Un-Metered Dry Material Feed, Metered Dry Material Feed: Choose the right handling and feeding method.

- Location of Dry Feed Deposited into the Tank: Proper material deposition is critical for efficiency.

10. Process Control and Monitoring

- Automation and Control Systems: Implement automation for precise control of your process.

- Monitoring Instrumentation: Utilize monitoring tools such as particle size analyzers.

- Real-Time Process Data Analysis: Real-time data analysis can help optimize your process on the fly.

11. Waste Management and Safety Considerations

- Management of Waste Products: Develop an effective waste management plan.

- Recycling or Reusing Waste Materials: Minimize waste by reusing or recycling materials.

- Dust and Fume Emissions: Control dust and fume emissions to maintain a safe working environment.

- Explosion Risks: Be aware of the potential explosion risks associated with certain materials or processes.

- Compliance with Safety Standards and Regulations: Ensure your operation complies with industry safety standards and regulations.

Conclusion

Wet milling and dispersion can be complex (to put it lightly, especially after this exercise). Understanding and carefully managing these numerous variables is essential to achieving the desired product quality, efficiency, and cost-effectiveness in your industrial processes. By systematically evaluating and optimizing each of these variables, you can navigate the maze of options and select the best wet milling solution for your needs.

If you have any questions or need guidance, reach out to the Schold, where we specialize in engineering and manufacturing media mill systems, from laboratory to large-scale production. Choosing the right media mill can affect an entire process, so it is always best to work with an expert. Save time, energy, and money by selecting the right equipment for YOU, and take your production to the next level today.