The VSM

Vertical Media Mill

The VSM Vertical Media Mill (also known as a bead mill or shot mill) is ideal for adding versatility to your grinding and dispersing process. The VSM is designed for milling a wide range of materials, including paints, inks, dyes, chemicals, adhesives, foods, pharmaceuticals, and more. For a small-scale, lab milling option, check out the EMI Lab Bead Mill. And for a post-mounted design, the VIM Immersion Mill is an optimal choice.

- Use as a stand-alone unit, integrated with a pre-mix/pre-dispersion process, or installed in series with different media sizes for multi-pass and sub-micron, high-production applications

- Handles materials with high viscosities or thixotropy, along with moisture and air-sensitive materials

- Quick and easy clean up between batches

- Available in a horizontal configuration depending on your operational requirements

Description

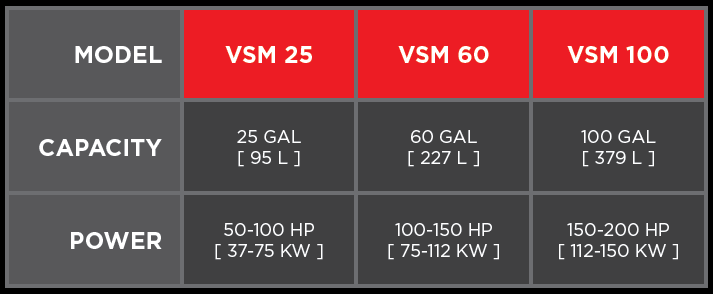

VSM Vertical Media Mill Specifications

VSM 25

- Capacity: 25 gallons (95 liters)

- Power: 50-100HP (37-75 kW)

VSM 60

- Capacity: 60 gallons (227 liters)

- Power: 100-150HP (75-112 kW)

VSM 100

- Capacity: 100 gallons (379 liters)

- Power: 150-200HP (112-150 kW)

VSM Vertical Media Mill Features

Small Footprint

The vertical design has a smaller footprint compared to other milling options, making it ideal for facilities with limited floorspace and/or tight production areas.

Vertical Chamber

The chamber’s vertical configuration promotes gravity-assisted flow, which aids in the circulation of the grinding media and product.

Motor Options

50-200 HP motor options available, providing a range of power to ensure optimal performance and efficiency in your operation.

Temperature Regulation

Liquid heating and cooling chamber options are available, a valuable feature for many products such as paints, inks, coatings, chemicals, etc.

What is a Vertical Media Mill?

For the best small-scale, laboratory bead mills on the market, visit our EMI Mills (formerly Eiger Mills) division to browse equipment options and to receive a quote!