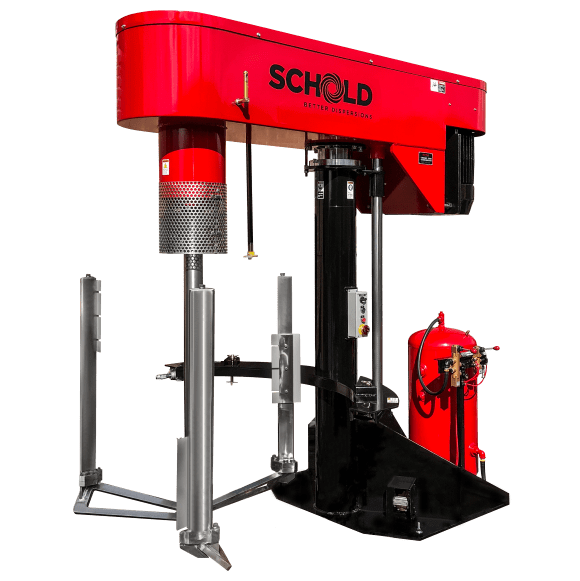

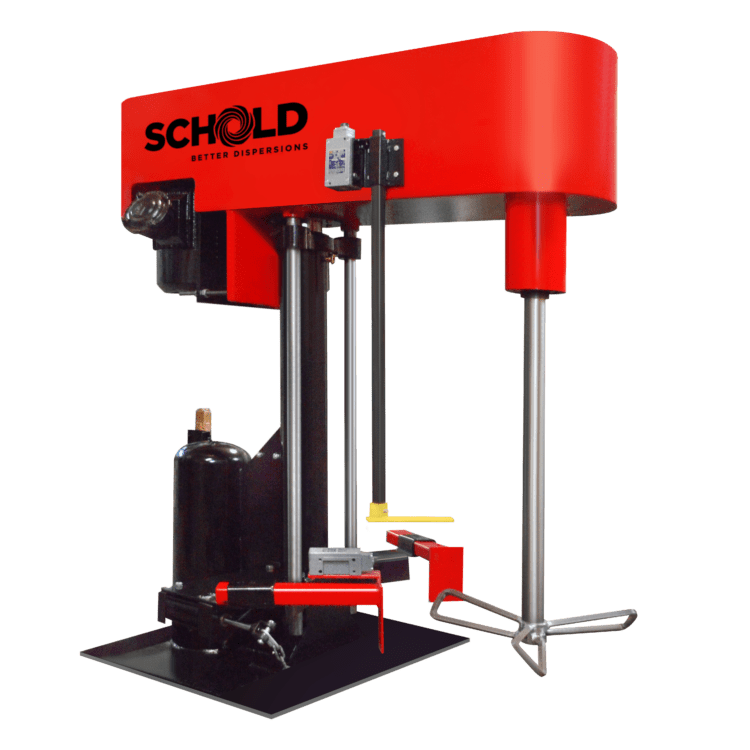

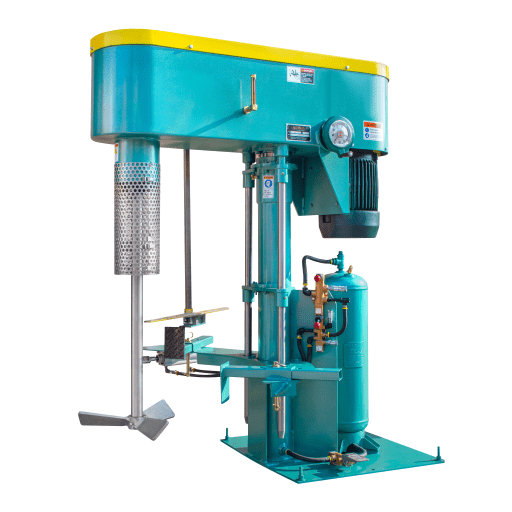

The VLS

Low-Speed Mixer

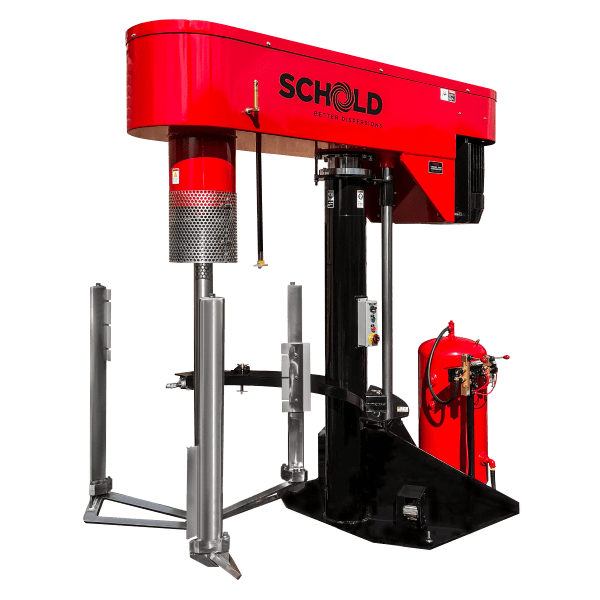

The VLS Low-Speed Mixer is ideal for mixing, blending, and agitating high-viscosity, poor-flowing products. Its robust, built to last, simple to operate, and customizable to suit your application and set-up. The VLS can be equipped with a standard bow-tie blade, or a helical/ribbon, anchor, axial flow, scraping, or other blade design to suit your mixing, blending, and agitation needs.

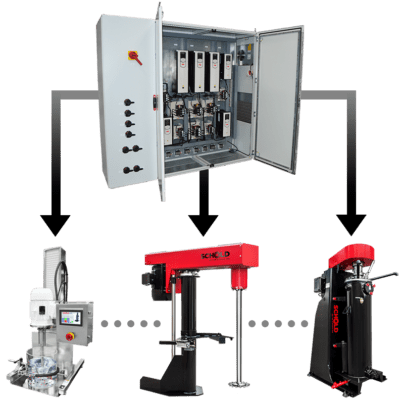

Whether you need the VLS at a stand-alone unit or integrated into a complete process system, Schold has the answer. Other post-mounted equipment options include the VHS High-Speed Disperser for high-shear mixing and our Multi-Shaft Mixers, which combines both high and low-speed mixing technology. Ask us about the best fit for your application.

Need to clear your tank after the batch?

Find discharge presses, tank washers, and more to round out your process

Description

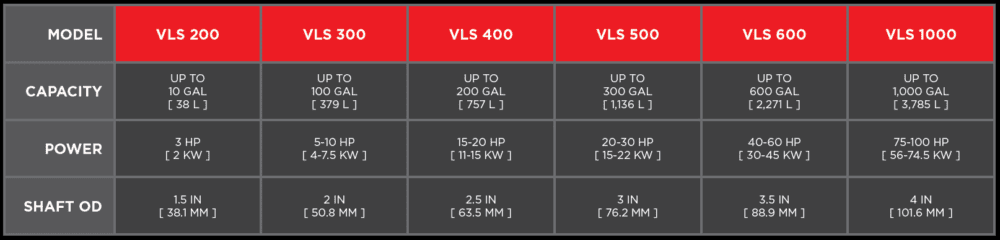

VLS Low-Speed Mixer Specifications

VLS 200:

- Capacity: 10 gallons (38 L)

- Power: 3 HP (2 kW)

- Shaft OD: 1.5 inches (38.1 mm)

VLS 300:

-

- Capacity: 100 gallons (379 L)

- Power: 5-10 HP (4-7.5 kW)

- Shaft OD: 2 inches (50.8 mm)

VLS 400

- Capacity: Up to 200 gallons (757 L)

- Power: 15-20 HP (11-15 kW)

- Shaft OD: 2.5 inches (63.5 mm)

VLS 500

- Capacity: Up to 300 gallons (1,136 L)

- Power: 20-30 HP (15-22 kW)

- Shaft OD: 3 inches (76.2 mm)

VLS 600

- Capacity: Up to 600 gallons (2,271 L)

- Power: 40-60 HP (30-45 kW)

- Shaft OD: 3.5 inches (88.9 mm)

VLS 1000

- Capacity: Up to 1,000 gallons (3,785 L)

- Power: 75-100 HP (56-74.5 kW)

- Shaft OD: 4 inches (101.6 mm)

VLS Low-Speed Mixer Features

Robust Design

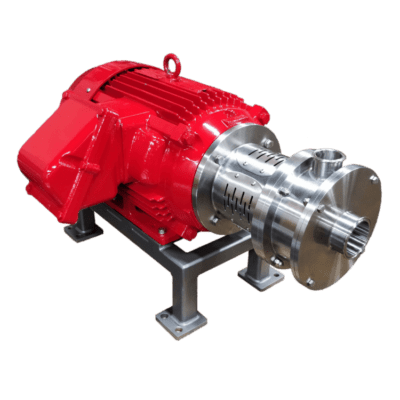

The VLS Low-Speed Mixer is designed to ensure stability during high-torque mixing, particularly at higher speeds with gear reduction capabilities. The computer-analyzed frame handles high vibration and stainless steel agitator shaft is tapered and turned for efficient dispersing, mixing, or blending.

Engineered for Safety

Specialized safety features include double-handed lift actuation, telescoping shaft guards, multiple safety switches, and optional integrated lid design for operator protection.

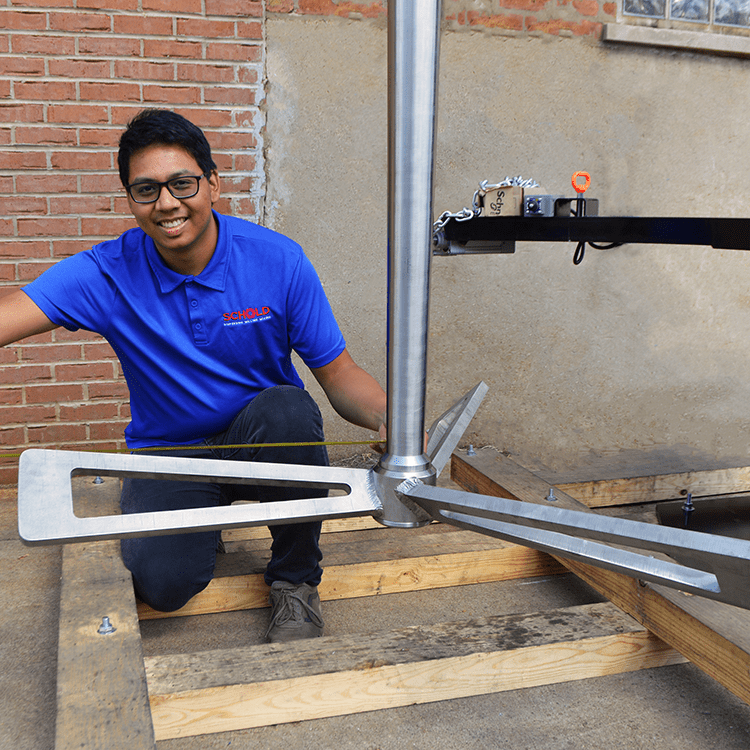

Mixing Blade Versatility

The bow-tie blade is standard for the VLS Low-Speed Mixer, but depending on your application, an alternate option may be optimal. We offer various blade designs including helical/ribbon, anchor, axial, scraping, and more. The shaft can also be customized as needed.

How Does Industrial Low-Speed Mixing Work?

The VLS Low-Speed Mixer operates by slowly turning a specialized blade within the material, generating enough torque to move even the thickest substances. This motion is ideal for blending and agitating poor-flowing materials that require thorough mixing without introducing too much air or heat. It also ensures gentle yet effective mixing, preventing damage to sensitive ingredients and maintaining the integrity of the product.

VLS Low-Speed Mixer with Food Application

Common Applications

-

Adhesives and Sealants

Mixing thick, sticky materials that require a consistent, smooth texture.

-

Paints and Coatings

Blending heavy pigments and fillers to achieve uniform color and viscosity.

-

Inks and Pigments

Agitating high-viscosity inks to maintain homogeneity and prevent settling.

-

Pharmaceuticals:

Gently mixing delicate, high-viscosity substances without compromising their properties.

-

Food Products:

Blending viscous food ingredients, such as doughs, pastes, and slurries, ensuring even distribution of components.

The VLS Low-Speed Mixer’s ability to handle the toughest materials with ease makes it an essential tool across these and many other industries, delivering reliable, high-quality results every time.