The VIM

Immersion Mill

The Variable Immersion Mill (VIM) is a staple in the milling industry. Immersion mills (or basket mills) have been around for years, but the VIM’s design and customizable options make it a leader in the market. For other milling options, check out the Laboratory Bead Mill, Horizontal Media Mill, and Vertical Media Mill.

- Provides rapid and efficient milling

- Creates vortex to pull product into “work zone” – media inside is agitated to break up and disperse particles in product

- Efficiently use small quantities of media

- Easy and economical cleaning

- Customizable to your application and production goals

Description

How Does Immersion Milling Work?

Advantages Over Traditional Milling

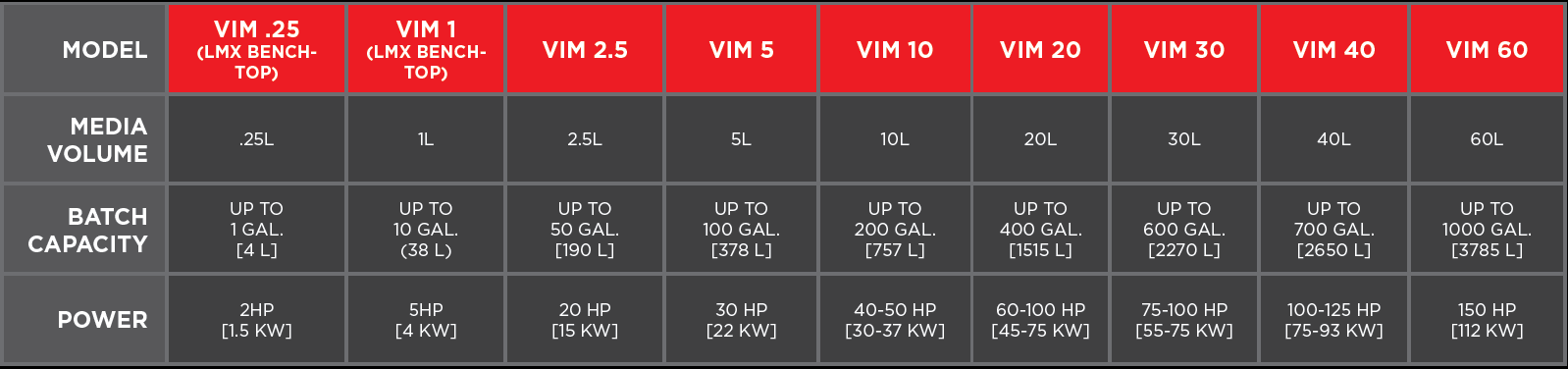

VIM Immersion Mill Specifications

VIM .25 (LMX Bench-top)

- Media Volume: 0.25L

- Batch Capacity: Up to 1 gal (4 L)

- Power: 2HP (1.5 kW)

VIM 1 (LMX Bench-top)

- Media Volume: 1L

- Batch Capacity: Up to 10 gal (38 L)

- Power: 5HP (4 kW)

VIM 2.5

- Media Volume: 2.5L

- Batch Capacity: Up to 50 gal (190 L)

- Power: 20HP (15 kW)

VIM 5

- Media Volume: 5L

- Batch Capacity: Up to 100 gal (378 L)

- Power: 30HP (22 kW)

VIM 10

- Media Volume: 10L

- Batch Capacity: Up to 200 gal (757 L)

- Power: 40-50HP (30-37 kW)

VIM 20

- Media Volume: 20L

- Batch Capacity: Up to 400 gal (1515 L)

- Power: 60-100HP (45-75 kW)

VIM 30

- Media Volume: 30L

- Batch Capacity: Up to 600 gal (2270 L)

- Power: 75-100HP (55-75 kW)

VIM 40

- Media Volume: 40L

- Batch Capacity: Up to 700 gal (2650 L)

- Power: 100-125HP (75-93 kW)

VIM 60

- Media Volume: 60L

- Batch Capacity: Up to 1000 gal (3785 L)

- Power: 150HP (112 kW)

VIM Immersion Mill Features

Batch Size Options

Available in a variety of volumes ranging from 1 gallon up to 1000 gallons to to tackle any-sized operation (beneficial for scaling-up to larger batches).

Customization and Versatility

Configure with various blade designs for your application, including wall-scraper blades, helical/spiral blades, and many more. When vessel diameter versatility is required, the VIM can be designed sans low-speed blade. The tub holder is easily adjustable to fit any size tank or vessel. Contact Schold experts for options!

Robust Design

The VIM Immersion Mill is built in-house with high-quality, durable materials to meet your requirements and precision-machined and balanced for safe operation.

Controls and Automation

Whether you prefer manual controls or automated controls with programmed recipes, Schold has a control system for you. From push buttons to touch-screen HMI screens, we have the solution.