The HSM

Horizontal Media Mill

The HSM Horizontal Media Mill (also known as a bead mill or shot mill) is ideal for adding efficiency to your grinding and dispersing process. The HSM is designed for milling a wide range of materials, including paints, inks, dyes, chemicals, adhesives, foods, pharmaceuticals, and more. For a small-scale, ;ab milling option, check out the EMI Lab Bead Mill. And for a post-mounted design, the VIM Immersion Mill is an optimal choice.

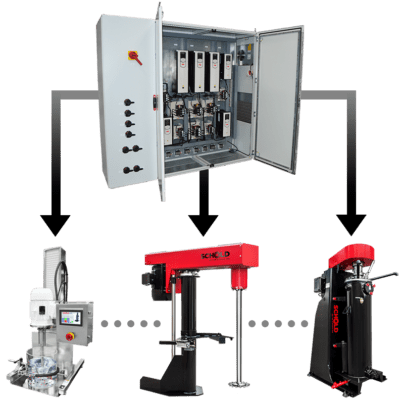

- Use as a stand-alone unit, integrated with a pre-mix/pre-dispersion process, or installed in series with different media sizes for multi-pass and sub-micron, high-production applications

- Handles materials with high viscosities or thixotropy, along with moisture and air-sensitive materials

- Quick and easy clean up between batches

- Available in a vertical configuration depending on your operational requirements

Description

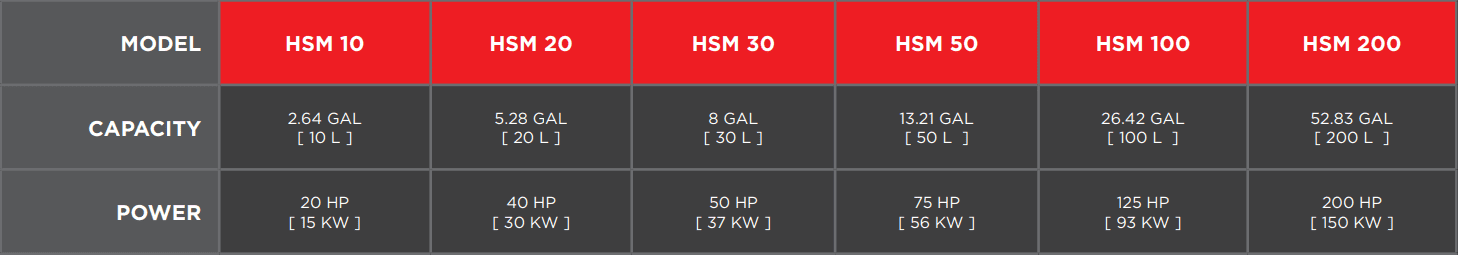

HSM Horizontal Media Mill Specifications

HSM 10

- Capacity: 2.64 gallons (10 liters)

- Power: 20HP (15 kW)

HSM 20

- Capacity: 5.28 gallons (20 liters)

- Power: 40HP (30 kW)

HSM 30

- Capacity: 8 gallons (30 liters)

- Power: 50HP (37 kW)

HSM 50

- Capacity: 13.21 gallons (50 liters)

- Power: 75HP (56 kW)

HSM 100

- Capacity: 26.42 gallons (100 liters)

- Power: 125HP (93 kW)

HSM 200

- Capacity: 52.83 gallons (200 liters)

- Power: 200HP (150 kW)

HSM Horizontal Media Mill Features

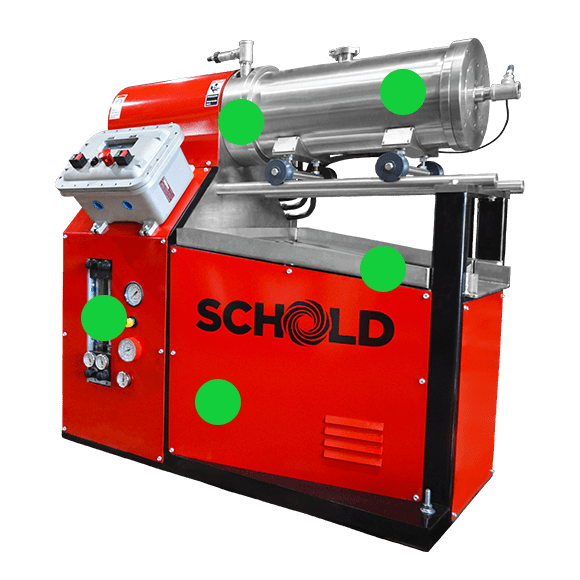

Motor Options

20-200 HP motor options available, providing a range of power to ensure optimal performance and efficiency in your operation.

Temperature Regulation

Liquid heating and cooling chamber options are available, a valuable feature for many products such as paints, inks, coatings, chemicals, etc. Dual or triple heating or cooling zones with flow rate meters are also included for precise milling.

Simple Cleaning

Clean-in-place: The housing rolls into cleaning position so no lifting is required. Additionally, a catch tray and cleaning cart with media separation screen is included for quick change overs.

What is a Horizontal Media Mill?

For a milling option with a smaller footprint, the VSM Vertical Media Mill is an optimal choice. And for the best small-scale, laboratory bead mills on the market, visit our EMI Mills (formerly Eiger Mills) division to browse equipment options and to receive a quote!