Industrial Mixing Equipment for Food and Beverage

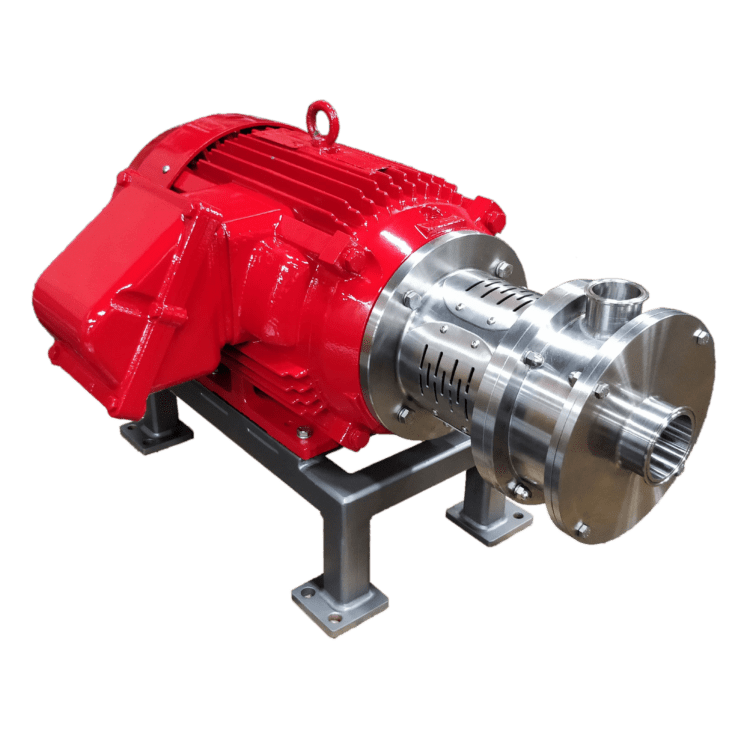

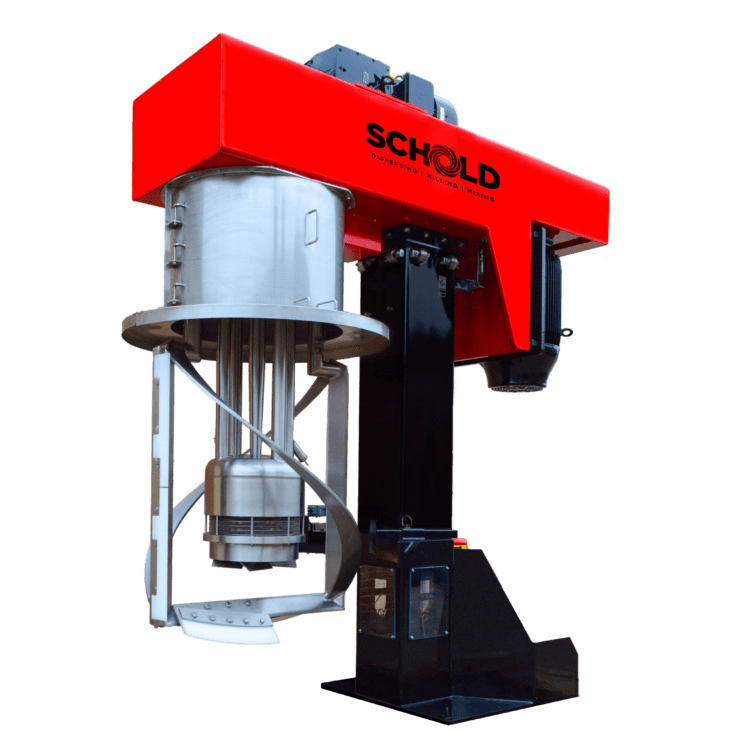

Schold provides industrial mixing equipment for food and beverage as a trusted partner in the industry. Our sanitary inline dispersers, high-shear mixers, low-speed mixers/blenders, immersion mills, and horizontal media mills, are widely used for processing a variety of these applications. From small, lab-sized batches to large, production-sized volumes, Schold has an equipment solution.

Industrial Mixing Equipment for Food and Beverage

Schold provides mixing equipment for food and beverage as a trusted partner in the industry. Our sanitary inline dispersers, high-shear mixers, low-speed mixers/blenders, immersion mills, and horizontal media mills, are widely used for processing a variety of these applications. From small, lab-sized batches to large, production-sized volumes, Schold has an equipment solution.

Recommended Industrial Mixing Equipment

Find common base models/designs of industrial mixing equipment for food and beverage. Questions? Need a quote? Schold can assist with questions or customized options specific for your application.

Schold Customer Spotlight

After 75+ years, Schold has accumulated a large, diverse customer base. We have hundreds of customers with industrial mixing equipment for food and beverage. Eisele’s Raw Honey is a family-owned business providing the highest-quality honey since 1981. To improve production, they added a Schold VLS 400 Low-Speed Mixer and it dramatically increased capacity and efficiency:

Eisele's Raw Honey

Indianapolis, IN

“Schold was the one place that didn’t just offer a stock industrial mixer, they provided a custom solution. A process that used to take hours is now just five minutes. It’s made such an impact that we are now thinking about expansion.”

-Kris Peterson, Owner

“The Schold VLS 400 Low-Speed Mixer changed the game for us by speeding up our process of filling buckets. Now we can stay ahead of demand and I have more time and energy for other tasks.”

-Bob Bordenkecher, Production Manager

OTHER TRUSTED COMPANIES USING SCHOLD INDUSTRIAL MIXING EQUIPMENT FOR FOOD AND BEVERAGE:

Product Applications

Food and beverage requires specific properties and performance. Our team of experts has worked with hundreds of companies in this space, and Schold equipment is custom designed to process these applications (along with many others):

Food (Primarily Solid Products)

- Salad Dressings & Condiments: Dispersing and mixing equipment emulsifies oil and water to create salad dressings and various condiments to ensure ingredients are evenly distributed and properly mixed.

- Soups & Sauces: Mixing equipment mixes and homogenizes ingredients in soups and sauces to ensure that the texture and consistency of the final product is consistent.

- Baby Food: Dispersing and mixing equipment creates purees and baby food to blend and homogenize the ingredients for a smooth texture.

- Pet Food: Mixing and milling equipment produces pet food to mix and homogenize the ingredients and to create various textures and shapes.

- Nut Butters: Milling equipment grinds nuts to create nut butters such as peanut butter and almond butter, ensuring the nuts are finely ground and properly mixed with other ingredients.

- Spices & Seasonings: Milling equipment grinds spices and seasonings such as pepper, salt, and cinnamon to ensure a consistent texture.

- Confectionery Coatings: Mixing equipment mixes ingredients for confectionery coatings such as chocolate and candy coatings to ensure the ingredients have a consistent texture.

- Baked Goods: Mixing and milling equipment is used in the processing of cakes, breads, cookies, pastries, etc. to ensure the product has a consistent texture and is easy to prepare.

- Snack Foods: Milling and mixing equipment grinds and mixes ingredients to create different textures and shapes for various types of snacks, such as chips, crackers, and popcorn.

- Protein Powders & Supplements: Mixing and milling equipment mixes and grinds ingredients for protein powders and supplements, ensuring a consistent texture.

- Ice Cream & Frozen Desserts: Mixing equipment mixes and homogenizes ingredients for ice cream and other frozen desserts, ensuring a smooth texture.

- Food Additives & Ingredients: Milling and dispersing equipment grinds and mixes ingredients to create a consistent texture and particle size for emulsifiers, thickeners, and stabilizers.

Beverages (Liquid Products)

- Soft Drinks: Mixing equipment mixes water, sugar, flavorings, and carbon dioxide in the production of soft drinks such as cola, lemonade, and energy drinks.

- Fruit Juices: Dispersing and mixing equipment mixes and homogenizes the fruit pulp, water, and sugar in the production of fruit juices such as orange, apple, and grape juice.

- Alcoholic Beverages: Mixing equipment mixes and homogenizes ingredients such as water, malt, hops, yeast, and grains in the production of alcoholic beverages such as beer, wine, and spirits.

- Sports Drinks: Dispersing and mixing equipment mixes water, sugar, electrolytes, and flavorings in the production of sports drinks such as energy drinks and electrolyte beverages.

- Dairy-based Beverages: Mixing and milling equipment mixes and homogenizes milk, fruits, and sweeteners in the production of dairy-based beverages such as milkshakes and smoothies.

- Teas & Coffees: Mixing and dispersing equipment mixes and homogenizes ingredients such as tea, coffee, sugar, and flavorings in the production of ready-to-drink teas and coffees.

Mixing/Processing Challenges

Food and beverage encounter a range of challenges during processing, specifically product consistency, quality, and compliance. Whether you choose Schold or another partner, selecting the proper industrial mixing equipment for food and beverage is crucial for overcoming these common challenges:

- Ingredient Homogeneity: Achieving consistent mixing and dispersion of ingredients to ensure uniformity in taste, texture, and appearance of food and beverage products.

- Viscosity Management: Handling variations in viscosity, especially in formulations with high-viscosity ingredients, to maintain proper flow characteristics during processing.

- Texture Control: Achieving the desired texture and mouthfeel in products like sauces, dressings, and beverages through precise dispersion and blending of ingredients.

- Temperature Sensitivity: Addressing the impact of temperature on sensitive ingredients, such as chocolate or dairy products, during processing to preserve taste and quality.

- Hygiene and Cleanability: Ensuring that dispersers, mixers, and mills are designed for easy cleaning to meet strict hygiene standards in food manufacturing.

- Dissolution of Soluble Ingredients: Achieving effective dissolution of soluble ingredients, such as powders or sugars, to prevent issues like grittiness in the final product.

- Fat and Emulsion Stability: Maintaining stability in emulsions and preventing issues related to fat separation in products like dressings or mayonnaise.

- Scale-Up Challenges: Adapting laboratory-scale processes to larger industrial scales while maintaining consistency, efficiency, and product quality in material dispersion and blending.

- Ingredient Homogeneity: Achieving consistent mixing and dispersion of ingredients to ensure uniformity in taste, texture, and appearance of food and beverage products.

- Viscosity Management: Handling variations in viscosity, especially in formulations with high-viscosity ingredients, to maintain proper flow characteristics during processing.

- Texture Control: Achieving the desired texture and mouthfeel in products like sauces, dressings, and beverages through precise dispersion and blending of ingredients.

- Temperature Sensitivity: Addressing the impact of temperature on sensitive ingredients, such as chocolate or dairy products, during processing to preserve taste and quality.

- Hygiene and Cleanability: Ensuring that dispersers, mixers, and mills are designed for easy cleaning to meet strict hygiene standards in food manufacturing.

- Dissolution of Soluble Ingredients: Achieving effective dissolution of soluble ingredients, such as powders or sugars, to prevent issues like grittiness in the final product.

- Fat and Emulsion Stability: Maintaining stability in emulsions and preventing issues related to fat separation in products like dressings or mayonnaise.

- Scale-Up Challenges: Adapting laboratory-scale processes to larger industrial scales while maintaining consistency, efficiency, and product quality in material dispersion and blending.