BATTERIES AND ELECTRONICS

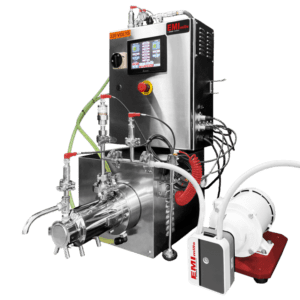

Schold is a trusted partner in the batteries and electronics industry, offering specialized high-speed dispersers, low-speed mixers/blenders, and media mills for laboratory and large-scale processing. Our equipment enables uniform dispersion of active materials, ensures consistent blending for electronic components, and achieves optimal particle size for battery and electronic device manufacturing.

Product Applications

Batteries and electronics power our daily lives, and the integration of laboratory and industrial dispersers, mixers, and mills is essential for production. Our team of experts works with many companies in this space, and our equipment is custom designed to process these applications (along with many others):

- Battery Electrode Material Preparation: Uniform dispersion and blending of electrode materials, such as active materials (e.g., lithium cobalt oxide), binders, and conductive additives, for lithium-ion batteries.

- Electrolyte Formulation: Precision mixing of electrolyte components, including solvents, salts, and additives, to create homogeneous electrolyte solutions for batteries.

- Adhesive and Sealant Manufacturing: Blending and dispersing materials for adhesives and sealants used in electronic component assembly and packaging.

- Printed Circuit Board (PCB) Ink Mixing: Homogeneous blending of inks containing conductive materials for PCB printing and manufacturing.

- Electronic Potting Compounds: Mixing and dispersing potting compounds to encapsulate and protect electronic components from environmental factors.

- Thermal Interface Material (TIM) Production: Precise blending of materials like thermal pastes and greases used as TIMs for efficient heat dissipation in electronic devices.

- Polymer Composite Processing: Dispersion and mixing of polymer composites used in electronic housings, connectors, and structural components.

- Conductive Paste Manufacturing: Creating conductive pastes for applications such as screen printing of conductive traces on flexible circuit boards.

- Cathode and Anode Slurry Mixing: Homogeneous mixing of slurries containing active materials, conductive additives, and binders for the production of electrodes in batteries.

- Electronic Ink Production: Dispersion and blending of materials for electronic inks used in applications like flexible displays and printed electronics.

- Ceramic Insulator Processing: Milling and dispersing ceramic materials for insulators and dielectrics in electronic components.

- Semiconductor Manufacturing: Mixing and dispersing materials for semiconductor fabrication, including photoresists, developers, and etchants.

- Battery Separator Coating: Coating processes involving the dispersion of materials for battery separators to enhance their properties.

- Dielectric Material Mixing: Precision blending of dielectric materials used in the production of capacitors and other electronic components.

- Electronic Component Encapsulation: Mixing and dispersing materials for encapsulating electronic components, providing protection against moisture and other environmental factors.

Processing Challenges

Batteries and electronics manufacturers encounter a spectrum of challenges during processing, which demands a meticulous approach to ensure product consistency, quality, and compliance. Whether you choose Schold or another partner, selecting the proper equipment is crucial for overcoming these common issues:

- Material Homogeneity: Ensuring uniform dispersion and blending of active materials, additives, and binders to achieve consistent material properties in battery electrodes and electronic components.

- Particle Size Control: Achieving precise control over particle size distribution during milling processes to meet the specific requirements of electronic materials and ensure optimal performance.

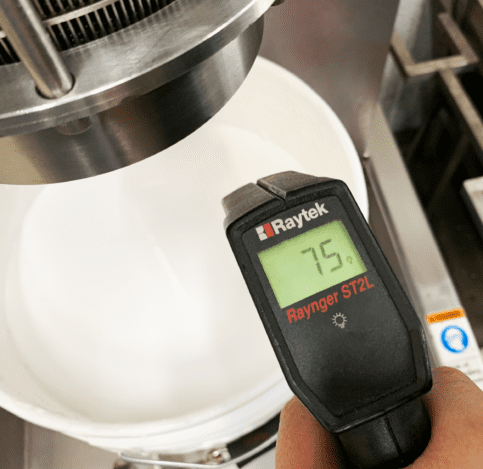

- Temperature Sensitivity: Managing the impact of temperature on sensitive materials during dispersing and mixing processes, especially for components like electrolytes and thermal interface materials.

- Viscosity Variation: Dealing with variations in viscosity, especially in complex formulations, to maintain proper flow characteristics during processing with dispersers and mixers.

- Catalyst Dispersion: Achieving effective dispersion of catalysts or conductive additives in electronic inks and pastes to ensure proper functionality in printed electronics and conductive traces.

- Residue Management: Managing residues and by-products generated during milling and mixing processes to prevent contamination and maintain the purity of materials.

- Scale-Up Challenges: Adapting laboratory-scale processes to larger industrial scales while maintaining precision, consistency, and efficiency in material dispersion and blending.

Recommended Processing Equipment

Here are the most common base models/designs used in the batteries and electronics industry. Schold experts can assist with any questions or customized options specific for your application.