Mixing Equipment for Chemicals

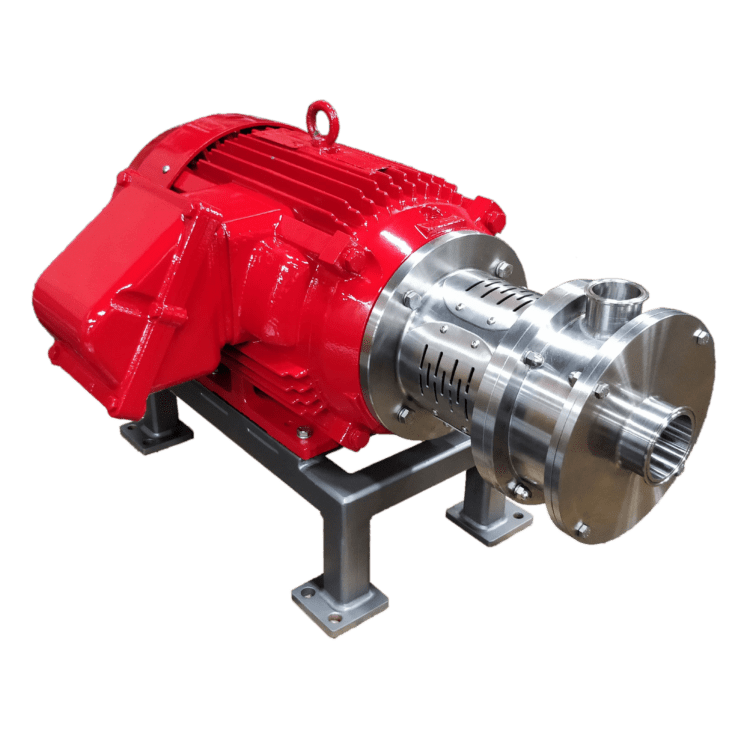

Schold provides mixing equipment for chemicals as a trusted leader in the industry. Our laboratory mixers, high-speed dispersers, high-shear mixers, multi-shaft mixers, and inline dispersers are widely used for processing a variety of chemical applications.

Mixing Equipment for Chemicals

Schold provides mixing equipment for chemicals as a trusted leader in the industry. Our laboratory mixers, high-speed dispersers, high-shear mixers, and inline dispersers are widely used for processing a variety of chemical applications.

Recommended Mixing Equipment

Find common base models/designs of mixing equipment for chemicals. Questions? Need a quote? Schold can assist with questions or customized options specific for your application.

TRUSTED COMPANIES USING SCHOLD MIXING EQUIPMENT FOR CHEMICALS:

Schold Customer Spotlight

After 75+ years, Schold has accumulated a large customer base. We have hundreds of customers with mixing equipment for chemicals – Daubert Chemical Company in Chicago is one of those many examples. Since 1935, Daubert has manufactured specialty coatings, lubricants, and adhesives and we are honored to be their exclusive mixing equipment partner.

“Schold’s commitment to quality has contributed to an overall improvement in our mixing efficiency and product quality. The assistance provided to our engineering and maintenance departments have helped us avoid expensive mistakes.”

-Mark Pawelski, VP of Operations

“I have so many good things to say. Schold has bailed me out so many times and made me look like a “rock star” with my co-workers. If you have a new dispersing, mixing, or milling project, these are the folks to engage. They make the impossible, possible.”

-Patrick Dwyer, Plant Engineer

Product Applications

Chemicals are used in a wide range of industries, which require specific properties and performance. Our team has worked with many companies in this space, and Schold equipment is custom designed to process these applications (along with many others):

- Industrial Chemicals: Used in manufacturing (electronics, textiles, paper production) and construction (cement, concrete, insulation); other examples include solvents, lubricants, and surfactants

- Agrochemicals: Protects crops from pests and diseases and promotes crop growth and yield (fertilizers, herbicides, pesticides)

- Household Products: Used in cleaning agents, laundry detergents, and disinfectants (surfactants, enzymes, bleaching agents)

- Petrochemicals: Derives from petroleum and used in the production of plastics, rubber, and other materials

- Pharmaceutical: APIs (Active Pharmaceutical Ingredients), excipients, and reagents for development of medicines and drugs (antibiotics, painkillers, vaccines)

- Cosmetic: Various products such as shampoos, lotions, makeup, and fragrances (preservatives, emulsifiers, fragrances)

- Food & Beverage: Used in production as preservatives, food coloring, and flavor enhancers

- Energy: Used in various forms of energy production, including oil and gas exploration, nuclear energy, and renewable energy sources such as wind and solar power

- Water Treatment: Purifies and disinfects drinking water

Mixing/Processing Challenges

Chemicals are essential to many industries and can be found everywhere in our daily lives. Processing methods vary, but the use of precise dispersing and mixing equipment is now standard practice. Whether you choose Schold or another partner, selecting the proper equipment is crucial for overcoming these common challenges:

- Chemical Homogeneity: Achieving consistent and thorough mixing to ensure uniform dispersion of chemical components, preventing variations in product quality.

- Reaction Control: Managing chemical reactions during mixing processes to control reaction kinetics, avoid side reactions, and achieve the desired product characteristics.

- Viscosity Management: Handling variations in viscosity, particularly in high-viscosity formulations, to maintain proper flow characteristics and ease of handling during processing.

- Temperature Control: Addressing the impact of temperature on chemical reactions and formulations to ensure stability, prevent degradation, and achieve desired product properties.

- Consistent Rheological Properties: Maintaining consistent rheological properties to ensure proper application and performance characteristics in different environmental conditions.

- High-Pressure Processing: Addressing challenges related to high-pressure processing, common in certain chemical reactions, to ensure equipment integrity and safety.

- Complex Formulations: Managing the challenges associated with complex formulations, such as those with multiple components, additives, or reactive species.

- Process Automation: Incorporating efficient process automation solutions to enhance productivity, consistency, and reproducibility in large-scale chemical manufacturing.

- Scale-Up Challenges: Adapting laboratory-scale processes to larger industrial scales while maintaining precision, consistency, and efficiency in material dispersion and blending.