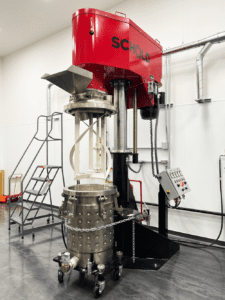

Multi-Shaft Mixer | An All-In-One Mixing Solution

Overview

In the industrial mixing space, challenges with consistency and overall product quality are common. Often times, just one inefficiency in the process leads to multiple (costly) issues. Multi-shaft mixers stand as formidable allies, blending high-speed and low-speed technologies to tackle tough applications. Beyond conventional mixing, these units serve as multiple machines combined into one. This fosters a consolidated approach that improves consistency and overall product quality.

What is a Multi-Shaft Mixer?

Engineered to address the intricacies of products with high viscosities and poor-flow characteristics, multi-shaft mixers redefine the possibilities in industrial mixing. By harmonizing high-speed dispersion with low-speed agitation, these units emerge as veritable multitaskers, encapsulating the functionality of several machines within a singular, robust design.

Versatility in Action: The unique feature of multi-shaft mixers lie in their ability to tackle a wide range of materials. The synergy of high and low-speed functions creates a dynamic “work zone,” facilitating the movement of challenging products for streamlined processing. Whether dealing with high-viscosity formulations or challenging raw materials, multi-shaft mixers transform the toughest materials into refined, consistent end products.

Customization Tailored to Your Needs: One size does not fit all, and Schold understands this implicitly. Multi-shaft mixers are versatile units that can be customized to the unique demands of your application. Whether configured as a co-axial, twin-shaft, or triple-shaft design, each is meticulously engineered to align with your production goals.

Overview

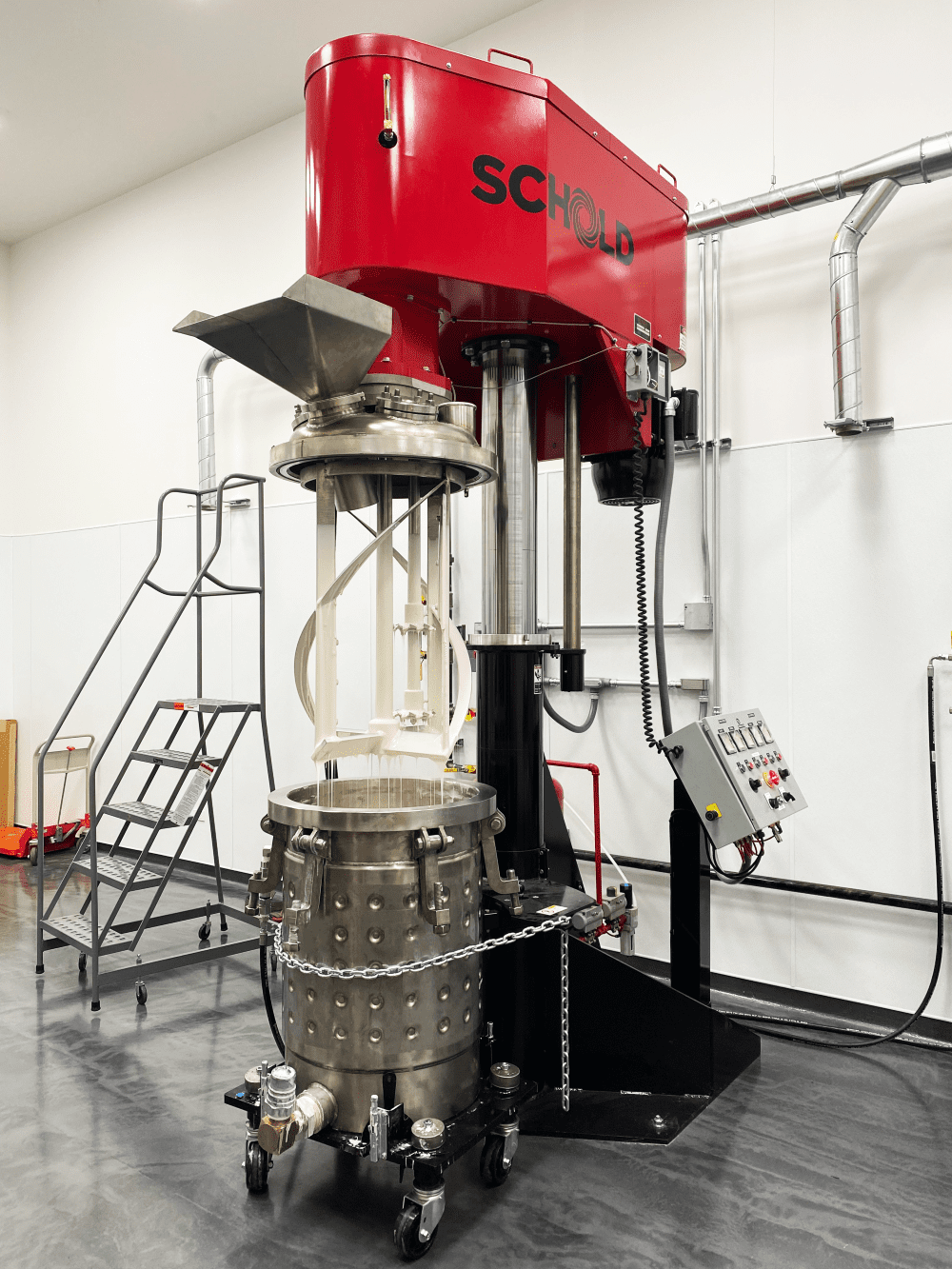

In the industrial mixing space, challenges with consistency and overall product quality are common. Often times, just one inefficiency in the process leads to multiple (costly) issues. Multi-shaft mixers stand as formidable allies, blending low and high-speed technologies to tackle the toughest applications. Beyond conventional mixing, these units serve as multiple machines combined into one. This fosters a consolidated approach that improves consistency and overall product quality.

What is a Multi-Shaft Mixer?

Engineered to address the intricacies of products with very high viscosities and poor-flow characteristics, multi-shaft mixers redefine the possibilities in industrial mixing. By harmonizing low-speed agitation with high-speed dispersion, these units emerge as veritable multitaskers, encapsulating the functionality of several machines within a singular, robust design.

Versatility in Action: The unique feature of multi-shaft mixers lie in their ability to tackle a wide range of materials. The synergy of high and low-speed functions creates a dynamic “work zone,” facilitating the movement of challenging products for streamlined processing. Whether dealing with high-viscosity formulations or challenging raw materials, multi-shaft mixers transform the toughest materials into refined, consistent end products.

Customization Tailored to Your Needs: One size does not fit all, and Schold understands this implicitly. Multi-shaft mixers are versatile units that can be customized to the unique demands of your application. Whether configured as a co-axial, twin-shaft, or triple-shaft design, each is meticulously engineered to align with your production goals.

Overview

In the industrial mixing space, challenges with consistency and overall product quality are common. Often times, just one inefficiency in the process leads to multiple (costly) issues. Multi-shaft mixers stand as formidable allies, blending low and high-speed technologies to tackle the toughest applications. Beyond conventional mixing, these units serve as multiple machines combined into one. This fosters a consolidated approach that improves consistency and overall product quality.

What is a Multi-Shaft Mixer?

Engineered to address the intricacies of products with very high viscosities and poor-flow characteristics, multi-shaft mixers redefine the possibilities in industrial mixing. By harmonizing low-speed agitation with high-speed dispersion, these units emerge as veritable multitaskers, encapsulating the functionality of several machines within a singular, robust design.

Versatility in Action: The unique feature of multi-shaft mixers lie in their ability to tackle a wide range of materials. The synergy of high and low-speed functions creates a dynamic “work zone,” facilitating the movement of challenging products for streamlined processing. Whether dealing with high-viscosity formulations or challenging raw materials, multi-shaft mixers transform the toughest materials into refined, consistent end products.

Customization Tailored to Your Needs: One size does not fit all, and Schold understands this implicitly. Multi-shaft mixers are versatile units that can be customized to the unique demands of your application. Whether configured as a co-axial, twin-shaft, or triple-shaft design, each is meticulously engineered to align with your production goals.

Multi-Shaft Mixer Types

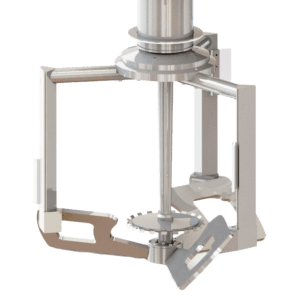

Co-Axial Mixer:

The co-axial mixer integrates both high-shear and low-speed blades rotating on the same axis. This dual configuration is ideal for higher viscosity products, providing an unparalleled solution for challenging formulations.

Twin-Shaft Mixer:

Designed for moderate to high viscosity formulations, the twin-shaft features a high-speed disperser and/or rotor stator offset from the low-speed anchor agitator or sweep blade. This allows for multiple high-speed blade configurations, enhancing versatility.

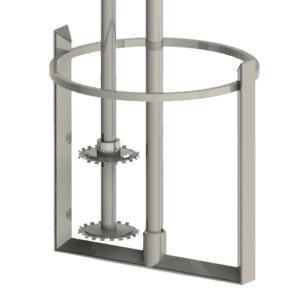

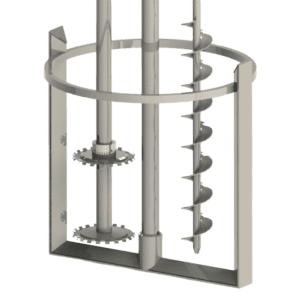

Triple-Shaft Mixer:

The triple-shaft includes both a low-speed agitator and a disperser and/or rotor stator. This design purées large solids at the start of a cycle, eliminating lumps, and may incorporate a lifting screw to suspend agglomerates in the finished batch.

Summary of Multi-Shaft Mixer Benefits

✔ Enhanced Product Quality:

The combination of high and low-speed agitation ensures thorough mixing, resulting in consistent batch-to-batch quality.

✔ Efficient Processing of Challenging Materials:

A multi-shaft mixer excels in moving products into the “work zone,” facilitating the processing of high viscosity, poor-flow materials.

✔ Customizable Configurations:

Tailor the mixer configuration to your specific application (co-axial, twin-shaft, or triple-shaft) for optimal performance.

✔ Versatility Across Industries:

From pharmaceuticals and chemicals to food applications, a multi-shaft mixer adapts to the diverse requirements of different industries.

✔ Increased Production Efficiency:

The dynamic, customizable configurations enhance production efficiency, reduce processing time, and improve overall manufacturing output.

✔ Precise Control and Optimization:

Benefit from precise control and optimization of mixing parameters, ensuring reproducibility and batch-to-batch consistency.

Summary of Multi-Shaft Mixer Benefits

✔ Enhanced Product Quality:

The combination of high and low-speed agitation ensures thorough mixing, resulting in consistent batch-to-batch quality.

✔ Efficient Processing of Challenging Materials:

A multi-shaft mixer excels in moving products into the “work zone,” facilitating the processing of high viscosity, poor-flow materials.

✔ Customizable Configurations:

Tailor the mixer configuration to your specific application (co-axial, twin-shaft, or triple-shaft) for optimal performance.

✔ Versatility Across Industries:

From pharmaceuticals and chemicals to food applications, a multi-shaft mixer adapts to the diverse requirements of different industries.

✔ Increased Production Efficiency:

The dynamic, customizable configurations enhance production efficiency, reduce processing time, and improve overall manufacturing output.

✔ Precise Control and Optimization:

Benefit from precise control and optimization of mixing parameters, ensuring reproducibility and batch-to-batch consistency.

Summary of Multi-Shaft Mixer Benefits

✔ Enhanced Product Quality:

The combination of high and low-speed agitation ensures thorough mixing, resulting in consistent batch-to-batch quality.

✔ Efficient Processing of Challenging Materials:

A multi-shaft mixer excels in moving products into the “work zone,” facilitating the processing of high viscosity, poor-flow materials.

✔ Customizable Configurations:

Tailor the mixer configuration to your specific application (co-axial, twin-shaft, or triple-shaft) for optimal performance.

✔ Versatility Across Industries:

From pharmaceuticals and chemicals to food applications, a multi-shaft mixer adapts to the diverse requirements of different industries.

✔ Increased Production Efficiency:

The dynamic, customizable configurations enhance production efficiency, reduce processing time, and improve overall manufacturing output.

✔ Precise Control and Optimization:

Benefit from precise control and optimization of mixing parameters, ensuring reproducibility and batch-to-batch consistency.

Is a Multi-Shaft Mixer a potential fit? If so, let’s get started.

Discover Schold Multi-Shaft Mixers – Explore configurations, learn about customization options, and transform your toughest materials into refined products.