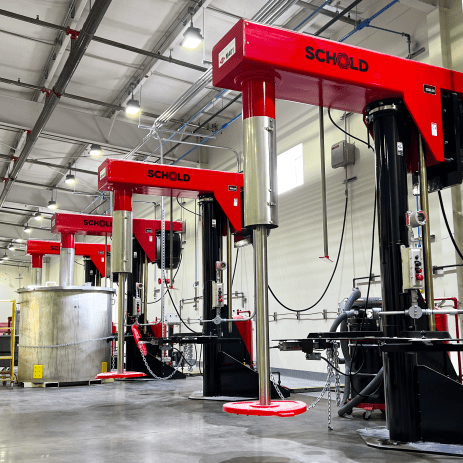

High-Shear Mixer Applications | A Quick Overview

What is a High-Shear Mixer?

A high-shear mixer utilizes high-speed blades or rotor-stator technology to generate intense shear forces, breaking down particles and droplets in a liquid. High-speed blades spinning at high velocities impart shear forces crucial for particle and droplet breakdown in various industrial processes. Alternatively, rotor-stator configurations create powerful shear forces with a rotating rotor fitted with blades or teeth within a stationary stator. This versatility allows high-shear mixers to meet specific processing needs in different applications.

High-Shear Mixer Types

Discover the various types of high-shear mixer options. Each configuration caters to specific processing needs, ensuring efficient emulsification, particle size reduction, and dispersion across various industrial applications.

Batch High-Shear Mixers

Designed for discrete batches, offering flexibility and easy customization.

Examples: VHS High-Speed Disperser and TMH Tank-Mount Disperser

Inline High-Shear Mixers

Integrates into production lines for continuous processing, ideal for large-scale operations.

Example: ILD Inline Disperser

Inline Powder Induction

Delivers flexibility and portability to handle various-sized mixing vessels. User-friendly operation maximizes equipment utility and simplifies material handling.

Example: ILD Inline Disperser Cart System

Laboratory-Scale High-Shear Mixers

Tailored for small-scale testing and research, providing precise control before scaling up.

Example: LMX Lab Mixer

Ultra-High-Shear Mixers

Process in single or multiple passes through a rotor–stator. Creates more shear than a standard high-speed blade, producing narrow particle-size distribution (sub-micron particle sizes).

Example: VRS Rotor Stator

Need Maximum Shearing?

After high-speed blades and rotor-stator technology, media mills take things to the next level. Round out your process with an EMI Lab Mill (lab/pilot batches) and HSM Horizontal Media Mill (large-scale production).

High-Shear Mixer Applications

Common applications of high-shear mixers include emulsification, particle size reduction, dispersion, homogenization, deagglomeration, and wet milling. All of these enhance product quality and production efficiency across various industries.

Emulsification

Emulsification is the process of mixing two immiscible liquids, such as oil and water, to form a stable emulsion. High-shear mixers are commonly used for emulsification in industries such as pharmaceuticals, cosmetics, and food. In the pharmaceutical industry, high-shear mixers are used to produce creams, ointments, and gels. With cosmetics, they are used to produce lotions, moisturizers, and sunscreens. And in the food industry, they produce sauces, dressings, and various condiments. Benefits include improved product stability, reduced processing time, and increased production efficiency.

Particle Size Reduction

Particle size reduction is the process of reducing the size of particles in a liquid or solid to improve their properties or performance. High-shear mixers are used for particle size reduction in industries such as chemicals, pigments, and coatings. Benefits of using high-shear mixers for particle size reduction include improved product quality, increased production efficiency, and reduced processing time. They also produce uniform particle sizes, which leads to improved product performance.

Dispersion

Dispersion is the process of mixing two or more substances to form a homogeneous mixture. High-shear mixers are used for dispersion in industries such as paints, coatings, and inks. Benefits of using high-shear mixers for dispersion include improved product quality, increased production efficiency, and reduced processing time. They also produce smaller particle sizes, which again leads to optimal results.

Homogenization

In various industries, homogenization plays a pivotal role in creating a consistent and uniform mixture by reducing particle size. High-shear mixers are a solid solution for this. In the food industry, for instance, homogenization is indispensable for producing smooth and consistent textures in products like sauces, creams, and dairy items. The precision and efficiency offered by high-shear mixers make them ideal for achieving the desired homogenization results.

Deagglomeration

Deagglomeration is a critical step in improving the quality and performance of products, particularly when agglomerated particles impact formulations. High-shear mixers break up agglomerated particles efficiently. For example, in the production of fertilizers, deagglomeration ensures an even distribution of nutrients, contributing to the efficacy of the final product.

Wet Milling

High-shear mixers play a crucial role in wet milling, a process that involves milling solid material in a liquid to create a slurry. High-shear mixers are commonly used in the pre-mix stage (before processing with a mill). The pre-mix step is incredibly important for mill longevity, reduced processing time, and optimal results, but often underutilized due to ignorance or misunderstanding. In the pharmaceutical industry, wet milling is employed to break down active pharmaceutical ingredients into smaller particles, enhancing bioavailability.

Questions? Quote Request?

Schold experts are here to assist. Get started by checking out Schold’s high-shear equipment (plus more):