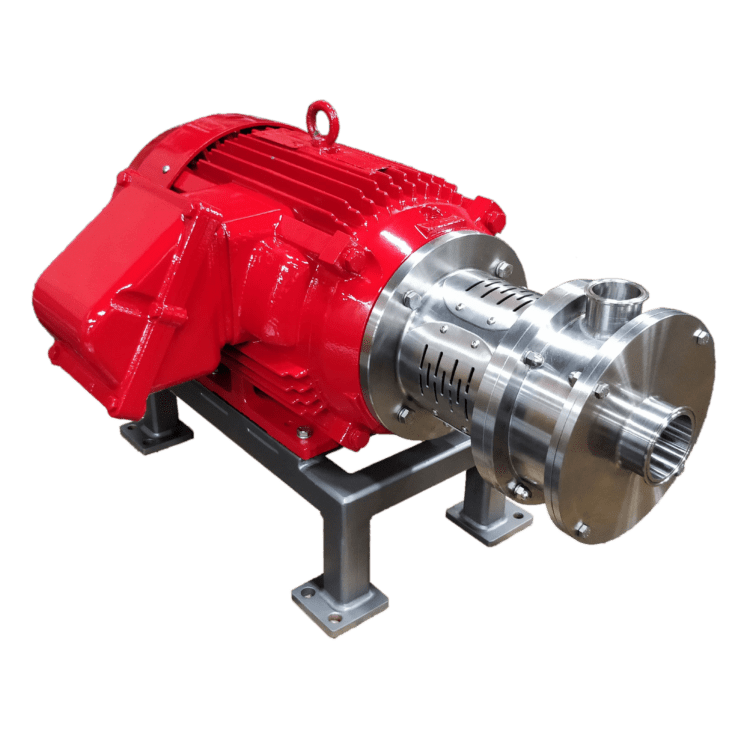

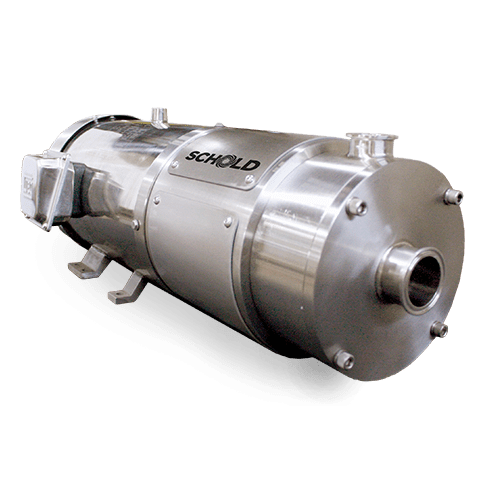

The ILD

Inline Disperser

The ILD Inline Disperser utilizes rotor-stator technology to process inline/batch applications. It quickly produces homogenous mixtures, suspensions, and emulsions for a wide range of products including chemicals, foods, pharmaceuticals, cosmetics, and many others.

- Compact size allows for simple integration with current process

- Disperses and mixes simultaneously as product is sheared between teeth of rotor

- Multiple inline configurations – single stage, dual stage, and more

- Various rotor and stator sizes available to meet production needs

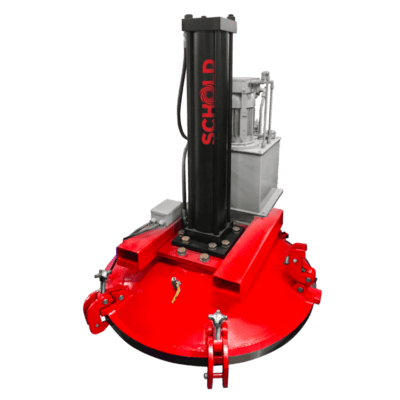

For a similar, but post-mounted option, find the VRS Rotor Stator. Need to process powders and liquids together? The ILD Inline Disperser Cart System is a common answer. For maximum shearing or particle reduction, browse our Media/Bead Mills.

Description

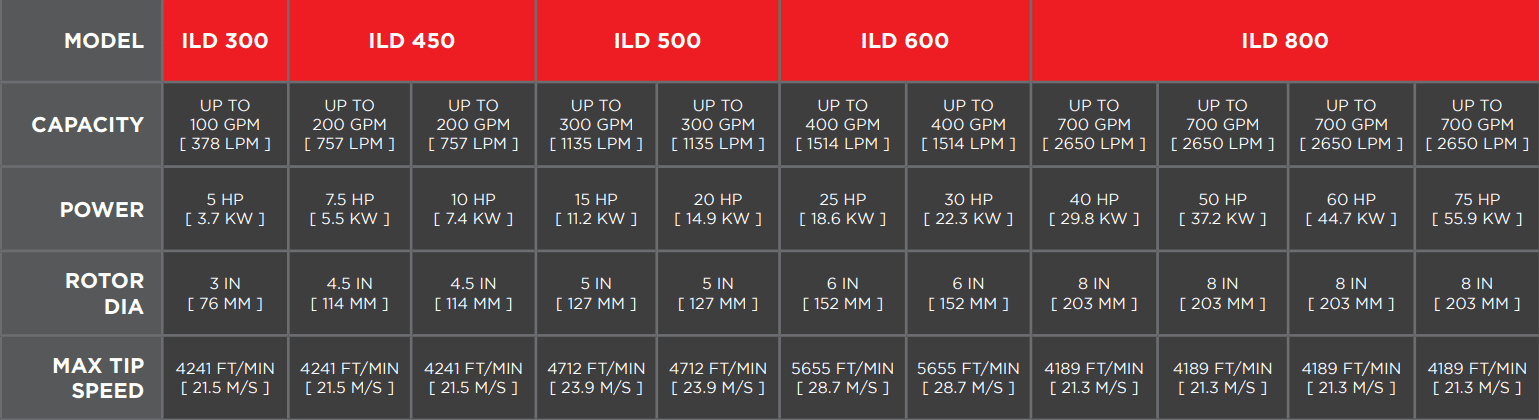

ILD Inline Disperser Specifications

ILD 300 (5 HP)

- Capacity: Up to 100 GPM (378 LPM)

- Power: 5HP (3.7 kW)

- Rotor Diameter: 3 inches (76 mm)

- Max Tip Speed: 4241 ft/min (21.5 m/s)

ILD 450 (7.5 HP)

- Capacity: Up to 200 GPM (757 LPM)

- Power: 7.5HP (5.5 kW)

- Rotor Diameter: 4.5 inches (114 mm)

- Max Tip Speed: 4241 ft/min (21.5 m/s)

ILD 450 (10 HP)

- Capacity: Up to 200 GPM (757 LPM)

- Power: 10HP (7.4 kW)

- Rotor Diameter: 4.5 inches (114 mm)

- Max Tip Speed: 4241 ft/min (21.5 m/s)

ILD 500 (15 HP)

- Capacity: Up to 300 GPM (1135 LPM)

- Power: 15HP (11.2 kW)

- Rotor Diameter: 5 inches (127 mm)

- Max Tip Speed: 4712 ft/min (23.9 m/s)

ILD 500 (20 HP)

- Capacity: Up to 300 GPM (1135 LPM)

- Power: 20HP (14.9 kW)

- Rotor Diameter: 5 inches (127 mm)

- Max Tip Speed: 4712 ft/min (23.9 m/s)

ILD 600 (25 HP)

- Capacity: Up to 400 GPM (1514 LPM)

- Power: 25HP (18.6 kW)

- Rotor Diameter: 6 inches (152 mm)

- Max Tip Speed: 5655 ft/min (28.7 m/s)

ILD 600 (30 HP)

- Capacity: Up to 400 GPM (1514 LPM)

- Power: 30HP (22.3 kW)

- Rotor Diameter: 6 inches (152 mm)

- Max Tip Speed: 5655 ft/min (28.7 m/s)

ILD 800 (40 HP)

- Capacity: Up to 700 GPM (2650 LPM)

- Power: 40HP (29.8 kW)

- Rotor Diameter: 8 inches (203 mm)

- Max Tip Speed: 4189 ft/min (21.3 m/s)

ILD 800 (50 HP)

- Capacity: Up to 700 GPM (2650 LPM)

- Power: 50HP (37.2 kW)

- Rotor Diameter: 8 inches (203 mm)

- Max Tip Speed: 4189 ft/min (21.3 m/s)

ILD 800 (60 HP)

- Capacity: Up to 700 GPM (2650 LPM)

- Power: 60HP (44.7 kW)

- Rotor Diameter: 8 inches (203 mm)

- Max Tip Speed: 4189 ft/min (21.3 m/s)

ILD 800 (75 HP)

- Capacity: Up to 700 GPM (2650 LPM)

- Power: 75HP (55.9 kW)

- Rotor Diameter: 8 inches (203 mm)

- Max Tip Speed: 4189 ft/min (21.3 m/s)

ILD Inline Disperser Features

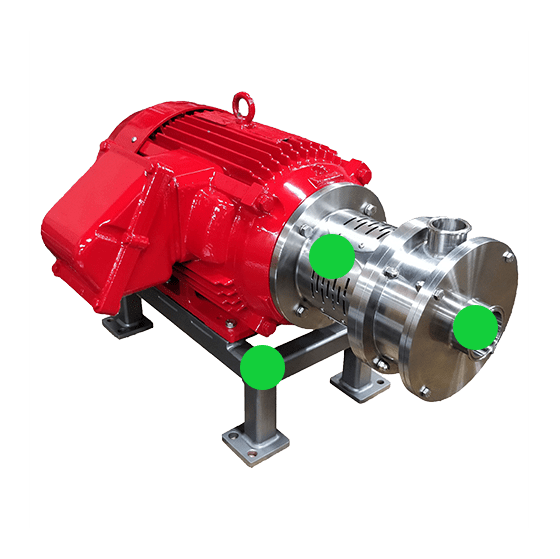

Small, Compact Design

The ILD Inline Disperser packs a punch with its compact size and range of horsepower options to fit your requirements. Additionally, the ILD seamlessly integrates into your current process using minimal floorspace. It

Customizable Configurations

The ILD is available is single or dual stage configuration, along with different slot sizes based on your application. We can also provide any entry and/or discharge equipment options to maximize overall process efficiency.

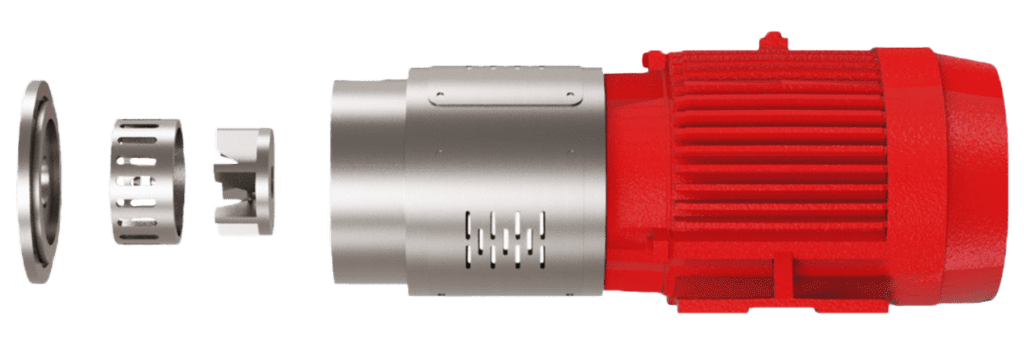

Quick Change-out Between Batches

The ILD Inline Disperser’s easy-open feature with robust fasteners allows for quick change-out of the grinding apparatus. This is ideal for minimizing costly downtime (and keeping operators happy).

How Does an Inline Disperser Work?

The product enters through the front inlet and is subjected to intense shearing as it passes through the rotor-stator assembly. This action ensures that powders and liquids are uniformly combined, resulting in a consistent and high-quality end product. The ILD Inline Disperser offers various configurations, including single-stage and dual-stage setups, to cater to different processing needs. The discharge can be oriented to any direction, facilitating convenient integration into downstream processes. With its compact design and customizable features, the ILD Inline Disperser is an adaptable solution for diverse industrial applications.

Is an Inline Disperser a Fit for My Application?

- Product Type: The ILD is capable of processing various products, including chemicals, pigments, food products, pharmaceuticals, and cosmetics. If your application involves creating suspensions, solutions, or emulsions, an inline disperser is likely a suitable choice.

- Processing Needs: For applications requiring high shear and fine particle reduction, the ILD’s dual-stage configuration provides enhanced shearing action. If your goal is to achieve quick and efficient processing with minimal downtime, the ILD’s versatile and customizable design will meet your needs.

- Sanitary Requirements: The ILD Inline Disperser offers sanitary options, making it ideal for food-grade applications. Its interchangeable stators and screens facilitate easy cleaning and maintenance, ensuring compliance with stringent hygiene standards.

- Space Constraints: With its compact footprint, the ILD can be easily integrated into existing systems or new processes without requiring significant space. This makes it a practical solution for facilities with limited space.