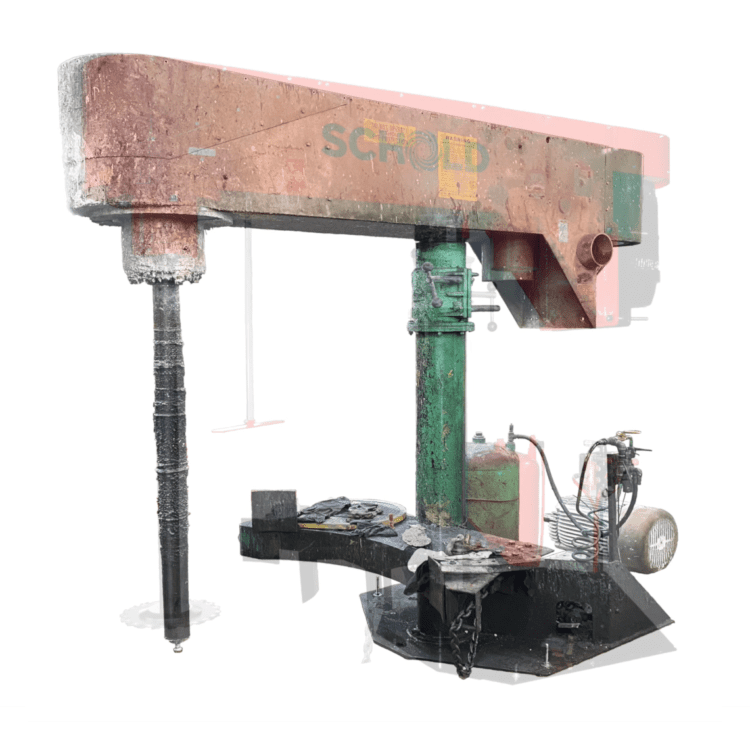

Refurbished High-Speed Disperser: Before & After

Option 1: Rehab Your Industrial Mixer

- Replace bearings, belts, and sheaves

Over time, these parts wear down, causing your machine to run less effectively. We replace them with high-quality parts for smoother, more reliable operation. - Swap out consumables

From piston seals to other high-wear parts, keeping consumables fresh is vital to preventing larger problems down the line. - Straight or replace shafts

Bent shafts can lead to improper mixing and a host of other issues. We straighten or replace them to restore precision. - Repair or replace blades

Damaged blades reduce dispersing efficiency and affect product quality. We assess your blades and replace them to optimize dispersion or mixing capability. - Install safety switches

We install or test any missing safety switches, ensuring your machine complies with the latest safety standards.

Option 2: Overhaul Your Industrial Mixer

For machines that need a complete revamp, Schold offers a full overhaul that brings your industrial disperser or mixer back to “like-new” condition. This service includes everything listed in the rehab option above, plus:

- Complete teardown and rebuild

We disassemble the entire machine, clean, inspect, and replace any damaged or worn components. This ensures your machine operates as if it were brand new. - Full sandblast and repaint of the frame

A fresh exterior not only enhances the aesthetics of your machine but also protects it from future wear and tear, especially in harsh industrial environments. - Polish pistons

Restoring pistons to peak condition ensures smoother operation and prolongs the life of the machine’s hydraulic system. - Replace hand and foot valves

These critical control components are restored to ensure reliable machine operation. - Control system upgrades

Upon request, we upgrade the control system of your machine to integrate the latest technology and safety features. Whether it is an enhanced touchscreen or automated controls, we make sure your machine is up to date. - 1-year warranty

With every full overhaul, we provide a comprehensive 1-year warranty, giving you peace of mind knowing that your equipment is covered.

Why Refurbishing Your Industrial Mixer Is a Smart Investment

- Cost savings

Refurbishing is often a fraction of the cost of buying new equipment. You get the same performance boost without the hefty price tag. - Improved efficiency

Worn-out parts reduce efficiency and increase production time. A refurbished machine can drastically improve throughput and reduce downtime. - Extended machine life

Regular maintenance and refurbishing extend the lifespan of your equipment, maximizing your investment. - Reduced downtime

A breakdown leads to costly production delays. By proactively refurbishing your machine, you avoid unplanned downtime and keep your operation running smoothly.

Schold’s expert team ensures that your equipment is restored to its full potential, so you can focus on what matters most—meeting production goals and delivering quality products to your customers. Contact us to get started on a discussion about your equipment and to request a quote.

Need to refurbish your media/bead mill?

We can assist with that too. Contact our EMI Mills division who specializes in that service.

Looking for pre-owned equipment?

Visit the Pre-Owned, Refurbished, Like-New Equipment page to check our current inventory. These machines are in-stock and ready for immediate shipment. Available for purchase or short-term rental.