MULTI-SHAFT

Mixers & Dispersers

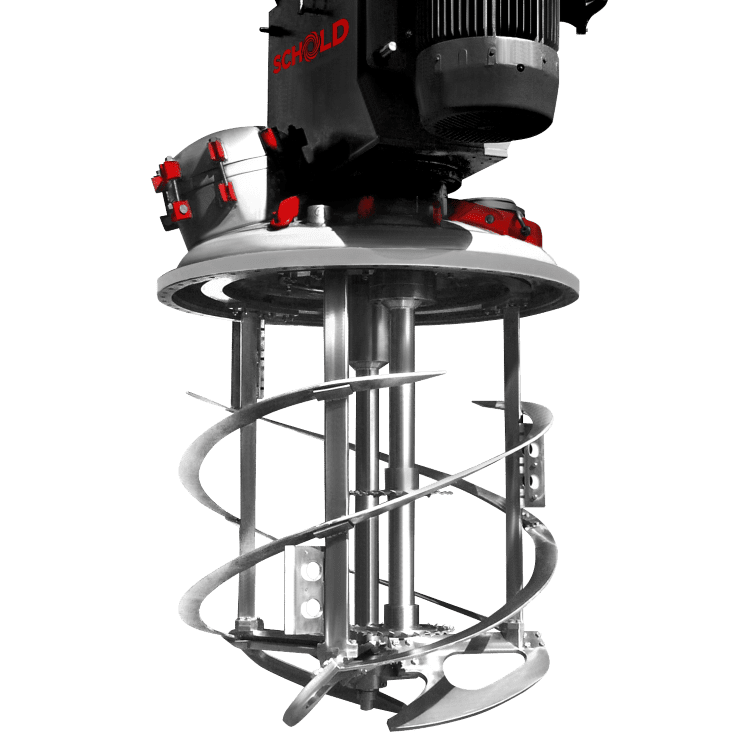

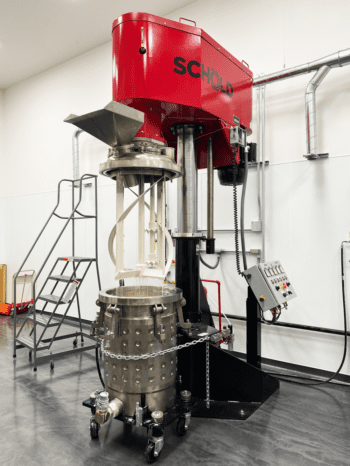

Multi-shaft mixers and dispersers tackle the toughest applications with high and low-speed technology, combining several machines into one. Don’t need a multi-shaft mixer design? Check out the VHS High-Speed Disperser for high-shear dispersing or the VLS Low-Speed Mixer for agitation and blending. And for stationary tank set-ups, a tank-mounted configuration offers minimal floorspace and fewer mechanical parts (compared to a post-mounted design).

- Designed for products with very high viscosities and poor flow characteristics

- Combines low-speed agitation with high-speed dispersion

- Engineered to move difficult products into the “work zone” for efficient processing

- Vacuum-capable process lids available if required

- Customizable blade configurations to suit your application and production goals

Find additional info on multi-shaft mixers in this blog post!

Description

Customizable Options and Configurations

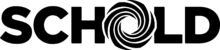

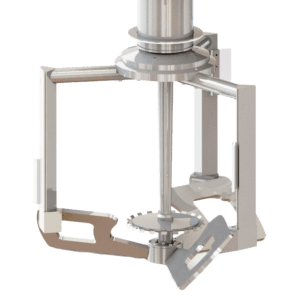

Co-Axial Mixer

- Integrates both high-shear and low-speed blade rotating on the same axis

- Low-speed agitator circulates product into the high-shear work zone

- Dual configuration is ideal for high viscosity products

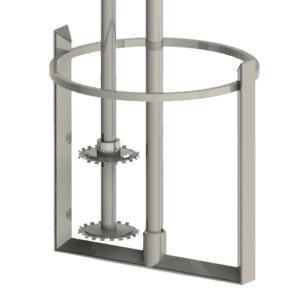

Twin-Shaft Mixer

- High-speed disperser and/or rotor stator is offset from a low-speed anchor agitator or sweep blade

- Designed for moderate to high viscosity formulations

- Multiple high-speed blade configurations

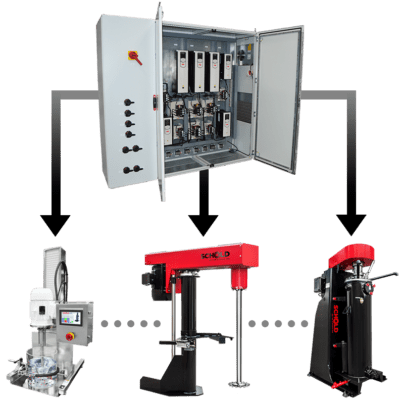

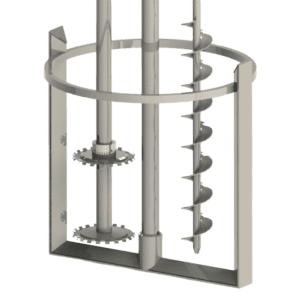

Triple-Shaft Mixer

- High-speed disperser and/or rotor stator along with a low-speed agitator

- Purée large solids at the start of a cycle and eliminate lumps

- Lifting screw may be incorporated to help suspend agglomerates in finished batch

Multi-Shaft Mixer Advantages

This combination streamlines operations, reduces processing time, and lowers energy costs, making multi-shaft mixers the preferred choice for industries requiring both versatility and precision.

Common Applications for Multi-Shaft Mixers

Paints, Inks, and Coatings

Ensures uniform dispersion and consistent product quality for decorative finishes, industrial coatings, specialty inks, and more.

Adhesives and Sealants

Provides robust blending and high shear for thick, sticky formulations, achieving homogeneity and optimal bonding strength.

Pharmaceuticals and Personal Care

Supports the precise mixing of creams, gels, and ointments, essential for product quality and effectiveness.

Food Processing

Enables smooth texture and flavor distribution in high-viscosity products like sauces, pastes, and more.

Questions? Need Something Else? Let's Get Started...

Additional info in blog post: Multi-Shaft Mixer | An All-In-One Mixing Solution