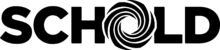

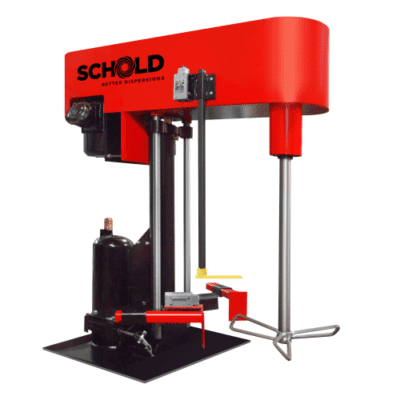

The VDM

Vacuum Drum Mixer

The Vacuum Drum Mixer is a great solution for customers who prefer to mix their product directly in the shipping container and under vacuum. The VDM is ideal for mixing or re-homogenizing viscous products where deaeration is critical and transferring to a vacuum rated tank is not practical.

- Drum/bucket is secured on steel platform with mounting bracket and tightening strap

- Vacuum bell lowers and vacuum is applied

- Single start/stop button runs entire process

- Two sight glasses provide visual access during processing

- Electric switch monitors level of vacuum applied

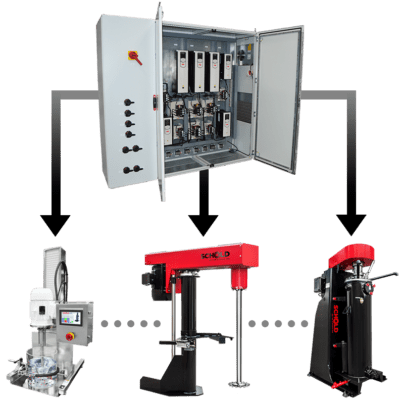

- Control panel automates vacuum/mixing process with easy-to-set timers

No need for a vacuum drum mixer? Common options: VHS High-Speed Disperser, VLS Low-Speed Mixer, Tank-Mount Mixers

Description

How Does Vacuum Drum Mixing Work?

1. Container Securing

The drum or bucket is placed on a robust steel platform and secured using a mounting bracket and tightening strap.

2. Vacuum Application

A vacuum bell is lowered over the container, creating an airtight seal. Vacuum is then applied to remove air, preventing oxidation and ensuring thorough mixing without air pockets.

3. Mixing Process

With the vacuum in place, the mixing process begins. A single start/stop button controls the entire operation, automating the process through an easy-to-use control panel.

4. Monitoring

Two sight glasses provide visual access to the product during mixing, while an electronic vacuum switch monitors the vacuum level to maintain optimal conditions.

Common Applications for Vacuum Drum Mixers

Adhesives and SealantsMixing viscous materials where air removal is critical to prevent air bubbles and ensure product consistency. |

Cosmetics and Personal Care ProductsHomogenizing creams, lotions, and gels under vacuum to achieve a smooth, aeration-free texture. |

PharmaceuticalsMixing ointments, gels, and other viscous formulations to ensure uniformity and prevent contamination by air. |

Paints, Inks, and CoatingsRe-homogenizing materials to maintain consistency and remove air that could cause defects or inconsistencies. |

Food and BeveragePreparing thick pastes, gels, or semi-solid products where maintaining a vacuum is necessary for quality and shelf-life. |

ChemicalsBlending reactive or viscous chemicals in a controlled, vacuum environment to ensure safety and uniform mixing. |

VDM Vacuum Drum Mixer Features

Robust Design |

Bell drum is certified for full vacuum, ensuring durability. The stainless steel agitator shaft is tapered and turned for high-efficiency dispersing. |

Versatile Motor Options |

Available in sizes ranging from 3 to 10 HP to suit various mixing needs, especially for smaller quantities. |

Adjustable Tub Holder |

Quick-adjust feature for minimal setup time and maximum efficiency. |

Convenient Operation |

Simple start/stop button controls and semi-automatic processes make it user-friendly and efficient. |

Space and Time Saver |

Mix directly in shipping containers without needing intermediate vessels, ideal for tight factory settings. |

Safety Focused |

Includes a pressure gauge, sight glasses, and an electronic vacuum switch for easy monitoring and safe operation under full vacuum conditions. |