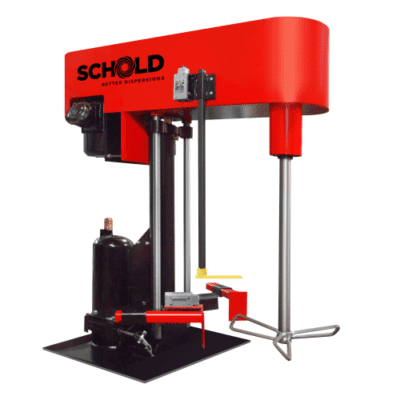

TANK-MOUNT

Mixers & Dispersers

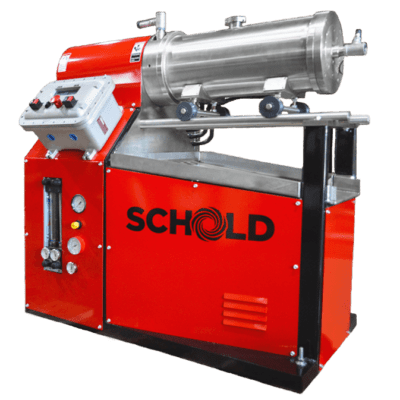

Schold mixing and dispersing equipment can be manufactured as tank-mounted models. Instead of having a leg or post to secure the dispersing head, all components are mounted directly on top of the process tank/vessel. Tank-mount mixers (or tank mixers) are ideal when the tank/vessel is stationary. For post-mounted designs, check out the VHS High-Speed Disperser and VLS Low-Speed Mixer.

- Saves space in tight factories

- Fewer mechanical parts mean less maintenance

- Various mount and blade configurations available based on your requirements

Need the tank and/or additional process equipment? We can engineer and supply tanks along with supporting equipment, such as entry feed systems, inert gas blanketing, vacuum systems, and more to complete your process. Contact us to determine the optimal solution for your operation.

Description

Bridge-Mount Tank Mixer

Flange-Mount Tank Mixer

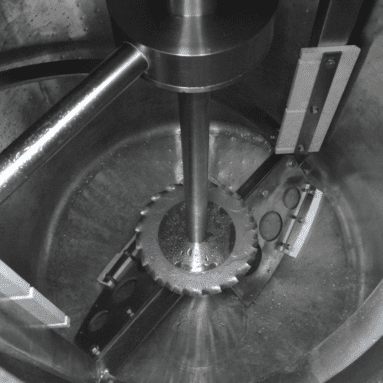

How Does Tank-Mount Mixing Work?

TMH 600 Tank-Mount Mixer Walk Around

TMH 3000 Tank-Mount Mixer Testing

Tank-Mount Mixer Features

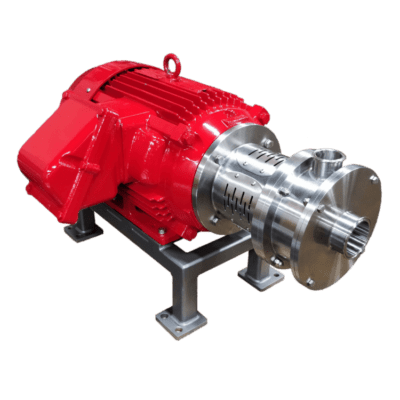

Motor and Horsepower Options

Tank-mount mixers are available in standard (TEFC) or explosion-proof (XP) configurations, with 2, 3, or 5 HP options.

Shaft Design

The direct-coupled shaft design enables efficient torque transfer, ensuring optimal power delivery and mixing performance.

Custom Configurations

Various blade options are available, including high-shear, helical/ribbon, axial-flow, multi-shaft designs, and more to suit mixing requirements. Additionally, pre-mix equipment, entry feed systems, inert gas blanketing, vacuum systems, pumps, etc. can be included to complete your mixing process.