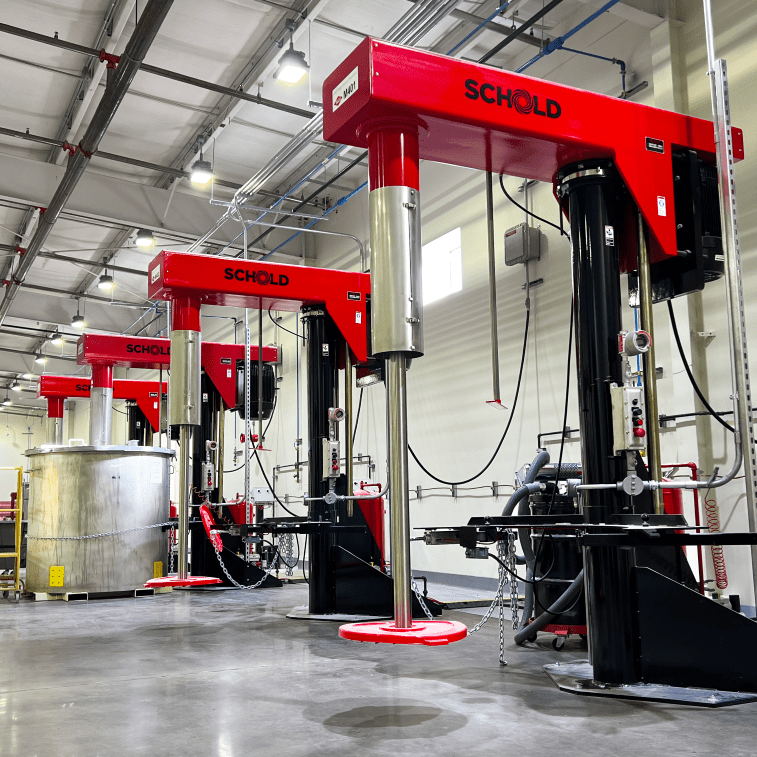

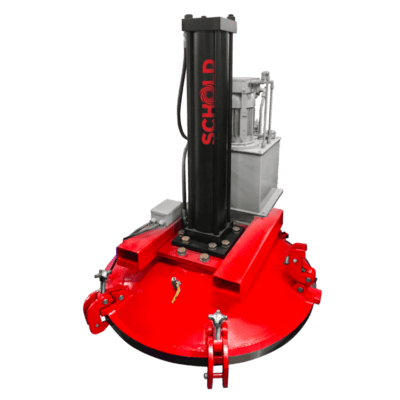

The VHS

High-Speed Disperser

The Schold High-Speed Disperser is a staple in the mixing and dispersing industry. Whether you are looking to disperse powders into a liquid or blend solvents together, the VHS is the solution. For a low-speed blending option, check out the VLS Low-Speed Mixer.

- Customizable to your exact specifications

- Ideal for dispersions up to 50,000 cP, 1,000,000+ cP possible with a multi-shaft design

- Robust design provides extreme stability at high speeds for tough batching production

- Stainless or carbon steel shaft is precision-balanced and control-tuned

- Engineered for safety with double-handed lift actuation, shaft guards, safety switches, and more

Need it quick? The VHS High-Speed Disperser is available with a Quick Ship option!

Description

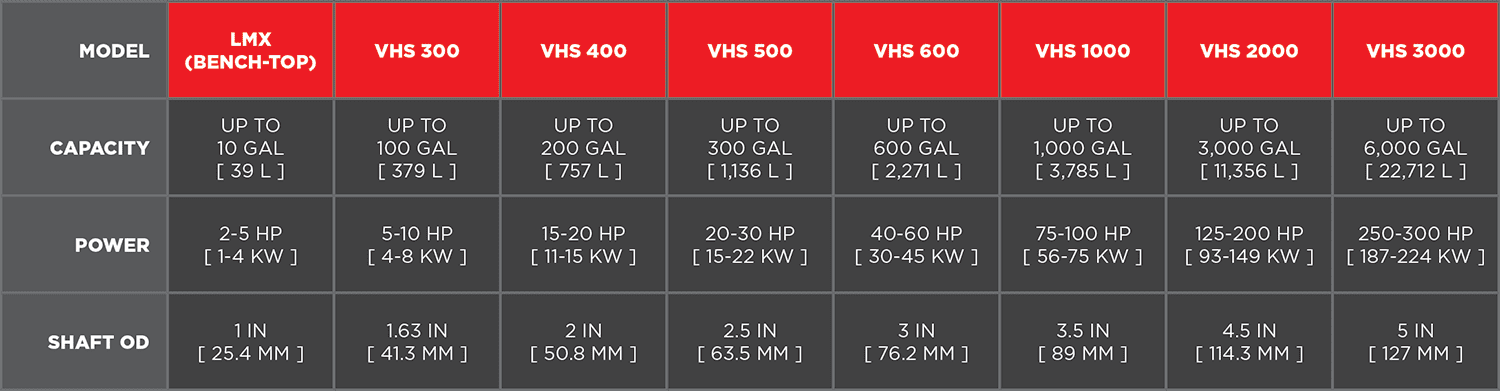

LMX (Bench-Top)

- Capacity: Up to 10 gallons [39 liters]

- Power: 2-5 HP [1-4 kW]

- Shaft OD: 1 inch [25.4 mm]

VHS 300

- Capacity: Up to 100 gallons [379 liters]

- Power: 5-10 HP [4-8 kW]

- Shaft OD: 1.63 inches [41.3 mm]

VHS 400

- Capacity: Up to 200 gallons [757 liters]

- Power: 15-20 HP [11-15 kW]

- Shaft OD: 2 inches [50.8 mm]

VHS 500

- Capacity: Up to 300 gallons [1,136 liters]

- Power: 20-30 HP [15-22 kW]

- Shaft OD: 2.5 inches [63.5 mm]

VHS 600

- Capacity: Up to 600 gallons [2,271 liters]

- Power: 40-60 HP [30-45 kW]

- Shaft OD: 3 inches [76.2 mm]

VHS 1000

- Capacity: Up to 1,000 gallons [3,785 liters]

- Power: 75-100 HP [56-75 kW]

- Shaft OD: 3.5 inches [89 mm]

VHS 2000

- Capacity: Up to 3,000 gallons [11,356 liters]

- Power: 125-200 HP [93-149 kW]

- Shaft OD: 4.5 inches [114.3 mm]

VHS 3000

- Capacity: Up to 6,000 gallons [22,712 liters]

- Power: 250-300 HP [187-224 kW]

- Shaft OD: 5 inches [127 mm]

VHS High-Speed Disperser Features

Versatile Motor Options

With sizes ranging from 3 to 300 HP, the VHS High-Speed Disperser provides the power needed to tackle tough materials, including high-viscosity applications. Whether you’re working with light fluids or dense mixtures, the motor options ensure consistent and thorough processing.

Robust, Stable Design

The computer-analyzed structural design of the VHS ensures stability, even at high speeds. This minimizes vibration and allows for uniform dispersion, eliminating issues like particle clumping or uneven mixing.

Adjustable Tub Holder

The quick-adjust tub holder accommodates various mix vessel diameters, offering flexibility for different batch sizes. A pneumatic chain-locking mechanism keeps the vessel secure, ensuring consistent performance without disruptions.

Advanced Safety Engineering

To address the risks associated with high-speed dispersing, the VHS High-Speed Disperser includes telescoping shaft guards, double-handed lift actuation, and multiple safety switches. For added protection, an optional integrated lid design is available, creating a safer working environment for operators.

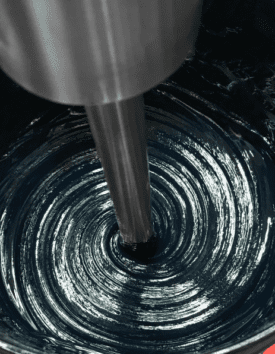

Precision-Tuned Shaft

The stainless or carbon steel shaft is precision-machined and balanced to ensure minimal run-out during operation. This accuracy prevents excessive heat generation and ensures even particle distribution for a consistent, high-quality result.

Common Applications for the VHS High-Speed Disperser

-

Paints and Coatings

Ideal for achieving uniform pigment dispersion and consistent color throughout high-performance coatings.

-

Inks and Dyes

Ensures precise mixing for vibrant and stable formulations, including digital and specialty inks.

-

Adhesives and Sealants

Handles viscous materials with ease, creating smooth, homogenous blends for reliable performance.

-

Chemicals

Blends solvents, resins, and other ingredients efficiently for industrial or consumer-grade products.

-

Food and Beverage

Mixes emulsions, syrups, and liquid ingredients while maintaining food-grade safety standards when required.

-

Cosmetics

Produces smooth, uniform dispersions for creams, lotions, and color cosmetics.

What is High-Speed Dispersing?

Ideal for applications such as paints, inks, coatings, adhesives, and sealants, high-speed dispersing ensures consistent texture, color, and stability in the final product. By optimizing mixing time and energy use, this process supports production for both small and large batches across diverse industries.

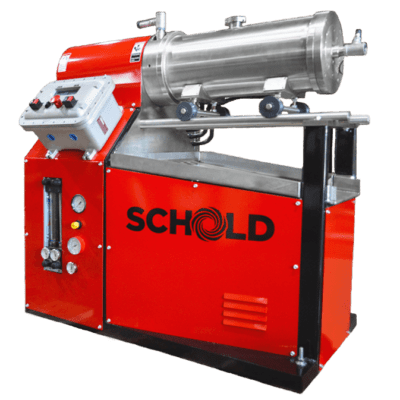

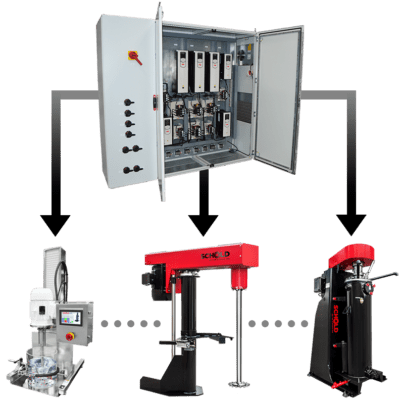

Need maximum particle reduction? The VHS High-Speed Disperser is common as a pre-mix step before running the product through a media/bead mill. For milling equipment options, check out our EMI Mills division. Between Schold and EMI, we can engineer a complete process system to suit your requirements.

High-Speed Dispersing Challenges

Addressing these challenges requires precision-engineered equipment capable of delivering consistent results while maintaining efficiency and safety, such as the features offered by the VHS High-Speed Disperser. Find operating instructions here.