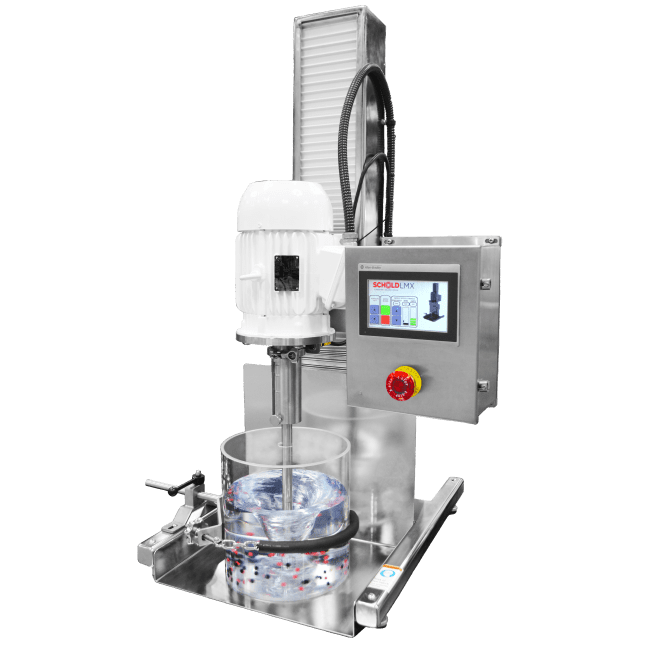

Colorlab Cosmetics: ''The LMX Lab Mixer is a Game Changer''

Colorlab Cosmetics, based in Rockford, Illinois with manufacturing in Williston, Vermont, manufactures high-end, cruelty-free makeup products for a range of clients. With a commitment to customer satisfaction, Colorlab sought a solution to improve their pigment dispersing process. After careful consideration, they chose Schold’s LMX Lab Mixer—and the results have been transformative.

Challenges Before Schold

Prior to using Schold’s LMX Lab Mixer, Colorlab Cosmetics relied on old mixing equipment that could not keep up with their production needs. We spoke with Charles Merrick, Quality Technician at Colorlab for his perspective:

“Our previous system lacked the torque and speed necessary to properly disperse our products. A 7-kilogram batch of castor oil and pigment that once took four (4) hours to disperse was completed in just 30 minutes with the LMX.”

Another key challenge was dispersing a propylene glycol pigment. With their old mixer, an 8-kilogram batch required dilution and still took 14 hours to process. In contrast, the LMX handled a combined 35-kilogram batch—more than 4x the original size—in just under two (2) hours. This resulted in nearly a 60-hour reduction in processing time (not including time/effort exhausted between batches).

“Not only did it take far less time, but the product came out exactly as it should—beautiful and ready for use in our finished products.”

The Schold Difference

The time savings have allowed Colorlab Cosmetics to reduce lead times, freeing up their production schedule and enabling them to meet increased demand without sacrificing quality.

“We cut our lead time from 12 to 8 weeks, which is great for customer satisfaction. Additionally, the return on investment was much shorter than expected. We planned on an 18-month payback, but energy savings alone cut it down to 11-months. With the productivity gains, we got our money back in less than 6 months.”

Not only has the LMX Lab Mixer improved throughput and product quality, but it boosted employee morale.

“A huge bonus is operator satisfaction… the team can now complete their tasks effectively, without fighting with equipment that is not up to the task. They’re happier and more efficient, which impacts our overall business positively.”

Why Schold?

In their search for new dispersing/mixing equipment, Colorlab explored multiple manufacturers, but Schold stood out not just for its top-tier equipment, but for its attention to detail and customer care.

“One of the most important questions Schold asked was about the particle size we needed to disperse down to. No one else asked us that… Schold cares about your specific process and product needs.”

When asked about their decision to choose Schold over competitors, Merrick emphasized the professionalism and support they received throughout the process.

“Schold made sure we got exactly what we needed. We felt confident we were investing in the right solution, and it’s paid off in ways we couldn’t have imagined.”

Ultimately, Merrick would recommend Schold to anyone.

“The professionalism, the expertise, and the support we received made all the difference. Working with Schold was easy. If you’re not considering them, you’re not thinking straight.”

To learn more about Colorlab Cosmetics and their range of products, visit their website or get in touch directly for inquiries. To find dispersing, milling, or mixing equipment for your cosmetics or personal care products, find the links below.