Air Over Oil Lift System

TWO HANDED SYSTEM

INSTALLATION

Connect the air supply to the hand valve and the machine is ready to operate. Always ensure that the air supply to the mixer is moisture free. This may entail adding an air dryer to the inlet of the hand valve.

OPERATION

AIR PRESSURE

Air pressure is allowed to build up in the tank when the lift system selector switch is toggled to “raise.” When the selector switch is toggled to “lower,” air will be exhausted from the tank.

Air pressure is allowed to build up in the tank when the lift system selector switch is toggled to “raise.” When the selector switch is toggled to “lower,” air will be exhausted from the tank.

RAISING THE LIFT

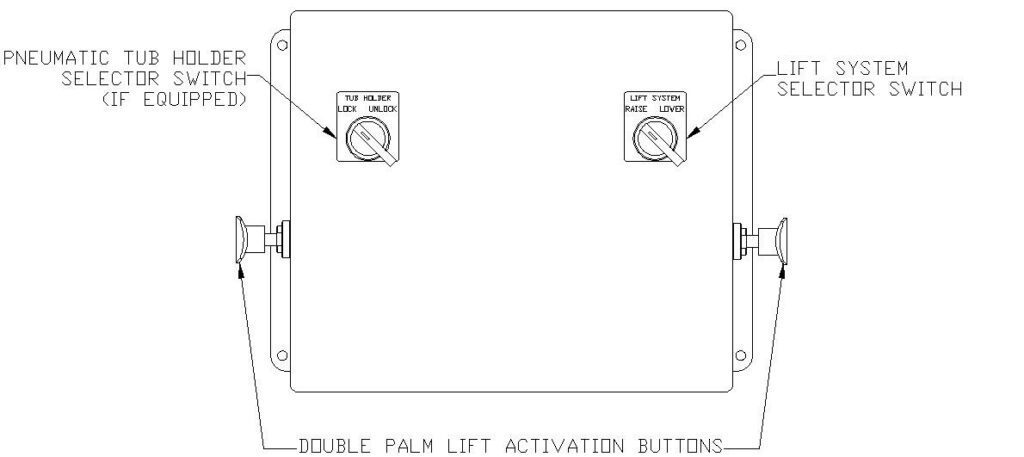

In order to raise the lift, the lift system selector swtich must be toggled to “raise” and the operator must depress both lift activation buttons on either side of the lift control enclosure. This permits the oil to flow from the tank under pressure, through the oil pipeline and into the lift. If one or both activation buttons is released, the lift will immediately stop moving.

In order to raise the lift, the lift system selector swtich must be toggled to “raise” and the operator must depress both lift activation buttons on either side of the lift control enclosure. This permits the oil to flow from the tank under pressure, through the oil pipeline and into the lift. If one or both activation buttons is released, the lift will immediately stop moving.

LIMIT OF RISE

The rise of the machine is mechanically limited by its design.

The rise of the machine is mechanically limited by its design.

LOWERING THE LIFT

In order to lower the lift, the operator must turn the lift system selector switch to “lower” and depress both lift activation buttons on either side of the lift control enclosure. This permits the tank to relieve pressure by exhausting air. The oil will then be pushed from the lift cylinder into the tank due to the weight of the machine head. This will allow the head to lower. If one or both activation buttons is released, the lift will immediately stop moving.

In order to lower the lift, the operator must turn the lift system selector switch to “lower” and depress both lift activation buttons on either side of the lift control enclosure. This permits the tank to relieve pressure by exhausting air. The oil will then be pushed from the lift cylinder into the tank due to the weight of the machine head. This will allow the head to lower. If one or both activation buttons is released, the lift will immediately stop moving.

SAFETY LOCKS

New machines are outfitted with a two hand operation safety device. To raise the machine, both activator switches must be depressed.

New machines are outfitted with a two hand operation safety device. To raise the machine, both activator switches must be depressed.

MAINTENANCE

GREASE AND OILING INSTRUCTIONS

Two grease fittings on top of the pulleys should be greased weekly. Main spindle bearings should be greased every three months. Torque tubes should be greased weekly. The oil cup on the top side of the cylinder should be filled with lubricating oil every week.

Two grease fittings on top of the pulleys should be greased weekly. Main spindle bearings should be greased every three months. Torque tubes should be greased weekly. The oil cup on the top side of the cylinder should be filled with lubricating oil every week.

HYDRAULIC OIL

Check the hydraulic oil level regularly. The tank should have approximately 20% air space. Check your manual for recommended oil fill volume. If there is moisture in the tank, all oil should be drained and refilled with new oil. Fill the tank with standard medium duty hydraulic fluid, mineral base.

Check the hydraulic oil level regularly. The tank should have approximately 20% air space. Check your manual for recommended oil fill volume. If there is moisture in the tank, all oil should be drained and refilled with new oil. Fill the tank with standard medium duty hydraulic fluid, mineral base.

HAND VALVE SYSTEM

INSTALLATION

Connect the air supply to the hand valve and the machine is ready to operate. Always ensure that the air supply to the mixer is moisture free. This may entail adding an air dryer to the inlet of the hand valve.

AIR PRESSURE

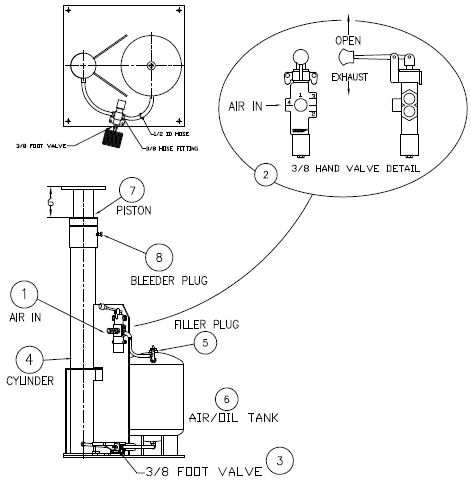

Air pressure in the tank is allowed to increase or decrease by the hand valve. Toggling the hand valve up allows compressed air from the plant air supply to flow into the tank, pressurizing it. Toggling the hand valve down exhausts air from the tank. To raise the lift, first toggle the hand valve up to pressurize the tank. This should take only 5-10 seconds.

Air pressure in the tank is allowed to increase or decrease by the hand valve. Toggling the hand valve up allows compressed air from the plant air supply to flow into the tank, pressurizing it. Toggling the hand valve down exhausts air from the tank. To raise the lift, first toggle the hand valve up to pressurize the tank. This should take only 5-10 seconds.

RAISING THE LIFT

In order to raise the lift, the tank must be pressurized and the foot valve must be open. Opening this valve permits the oil to flow from the tank under pressure, through the oil pipeline and into the lifted foot valve is a self-closing valve under spring pressure. The instant the operator removes pressure from the handle of the foot valve, it will spring to a closed position, shutting off the oil pressure of the lift and stopping the rise immediately.

In order to raise the lift, the tank must be pressurized and the foot valve must be open. Opening this valve permits the oil to flow from the tank under pressure, through the oil pipeline and into the lifted foot valve is a self-closing valve under spring pressure. The instant the operator removes pressure from the handle of the foot valve, it will spring to a closed position, shutting off the oil pressure of the lift and stopping the rise immediately.

LIMIT OF RISE

The rise of the machine is mechanically limited by its design.

The rise of the machine is mechanically limited by its design.

LOWERING THE LIFT

In order to lower the lift, pressure in the tank must be relieved. To do this, toggle the hand valve down into the exhaust position. When all the air pressure has been exhausted from the tank, depress the foot valve, permitting the oil to flow back into the tank from the weight of the lift. Any time pressure is removed from the foot valve, the spring pressure will close it and the lowering operation will stop immediately.

In order to lower the lift, pressure in the tank must be relieved. To do this, toggle the hand valve down into the exhaust position. When all the air pressure has been exhausted from the tank, depress the foot valve, permitting the oil to flow back into the tank from the weight of the lift. Any time pressure is removed from the foot valve, the spring pressure will close it and the lowering operation will stop immediately.